Product Safety & Security

Quality Policy

- Aim for “safe and reliable quality” our customers can depend on.

- Strive to raise awareness of quality, standardize internal processes, and pursue efficient work. (people, organization, systems, and work)

- Promote environmental impact reduction with consideration for climate change across all business processes, including development, design, procurement, production, logistics, sales, services, and management.

- Ensure products meet legal standards to improve customer satisfaction and social trust.

- Build a quality management system and continuously improve the business process by setting goals, implementing actions, and evaluating outcomes.

* Approved on July 22, 2025; scheduled to be applied from FY2026

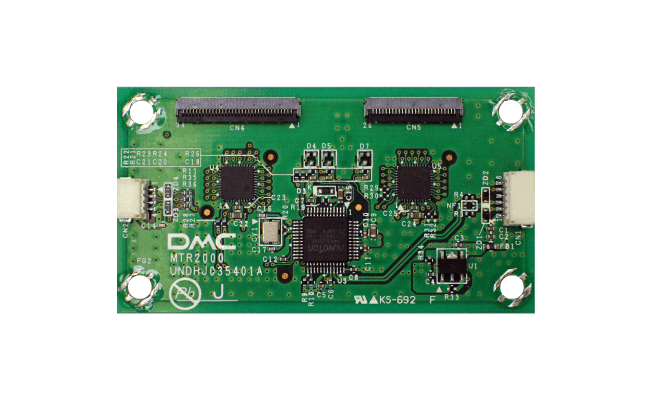

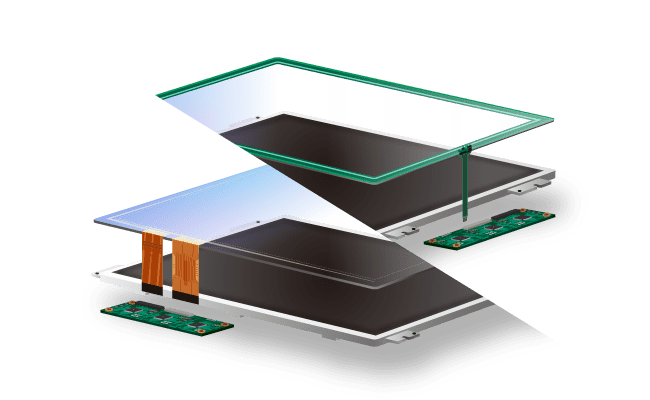

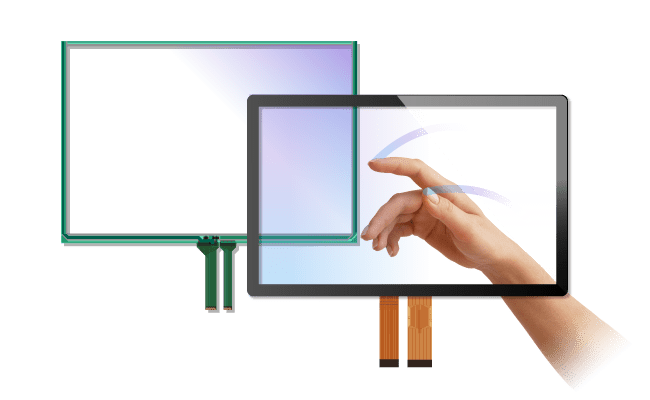

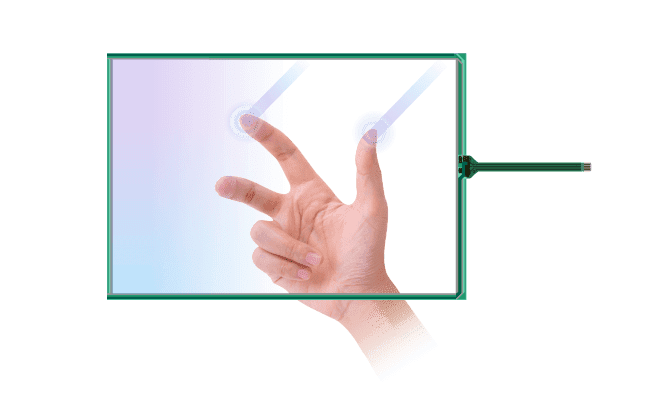

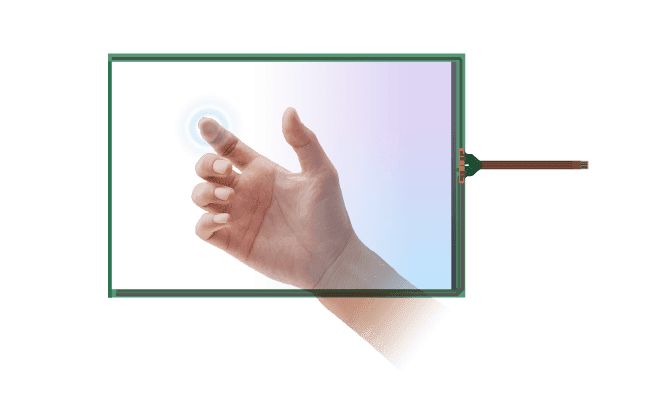

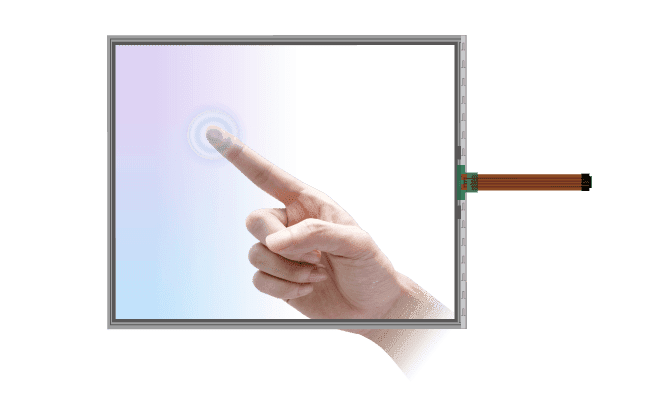

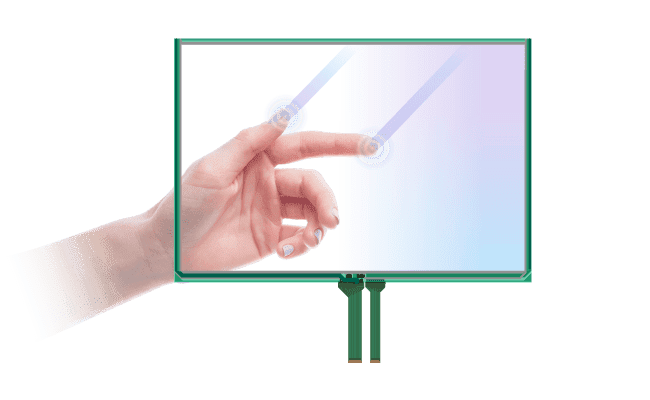

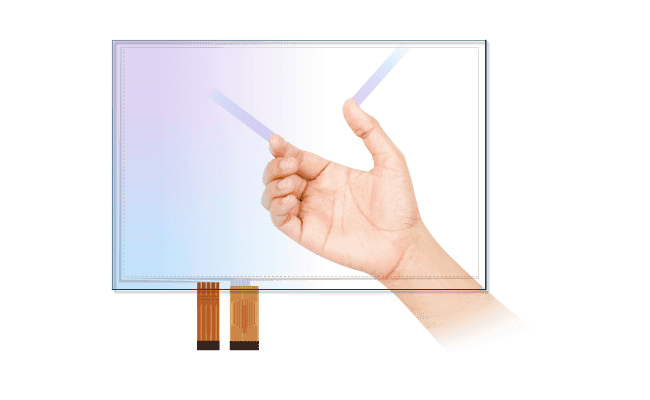

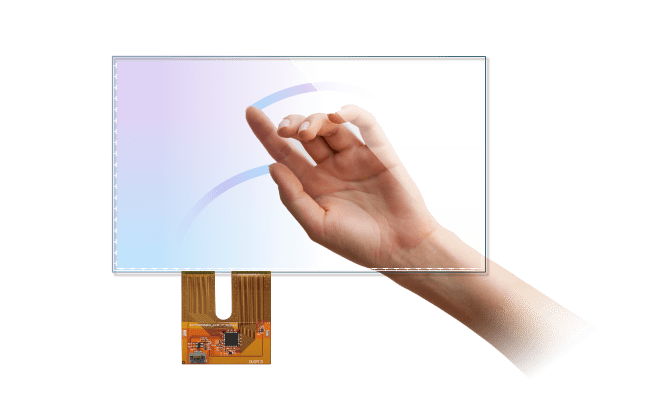

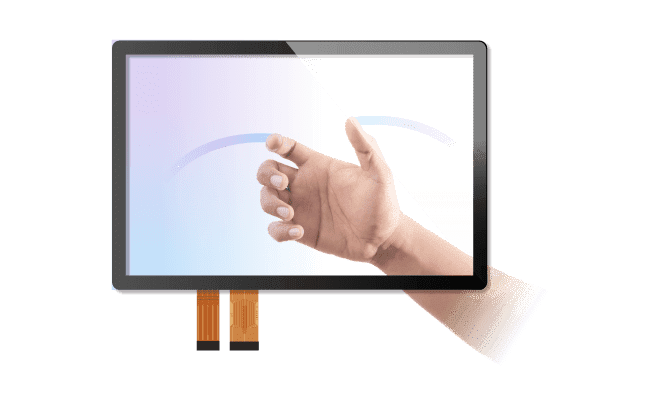

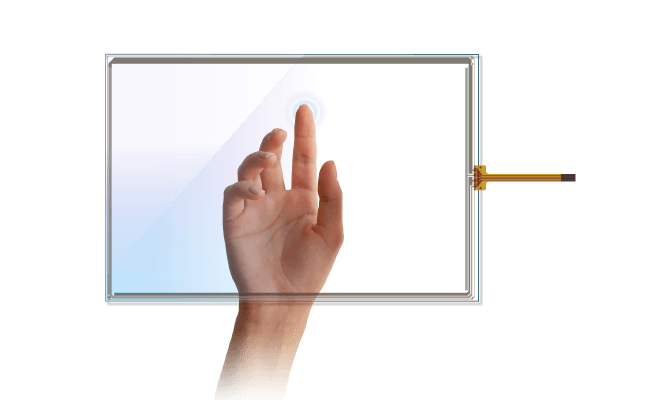

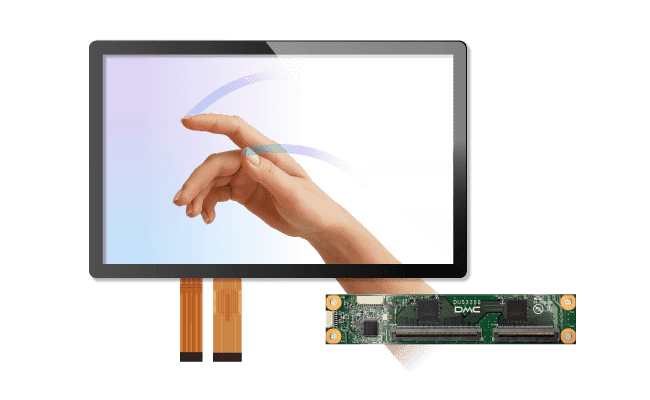

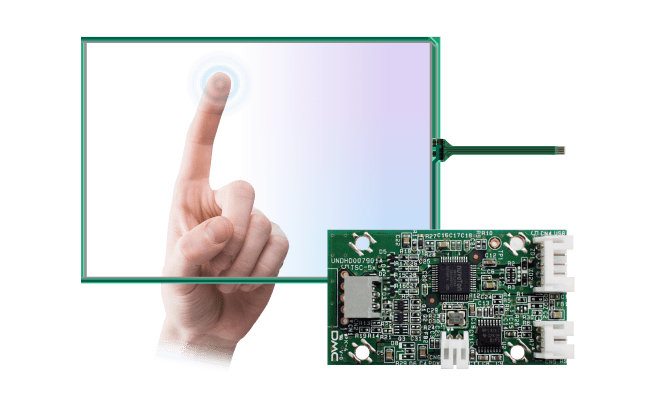

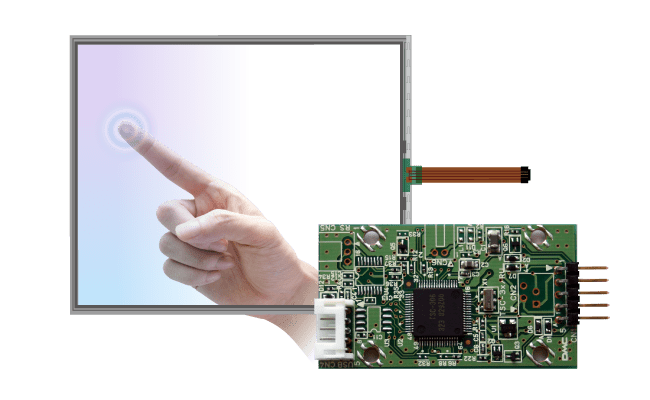

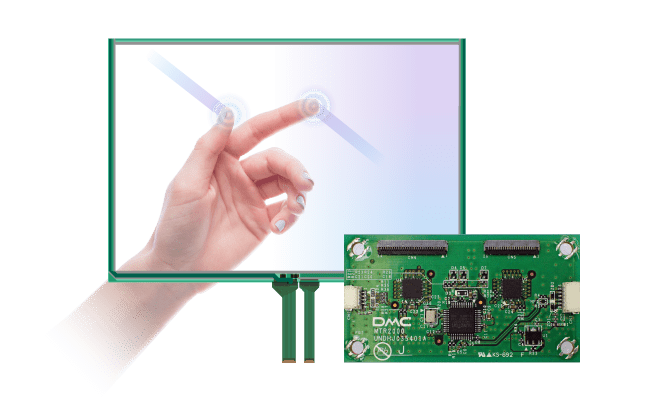

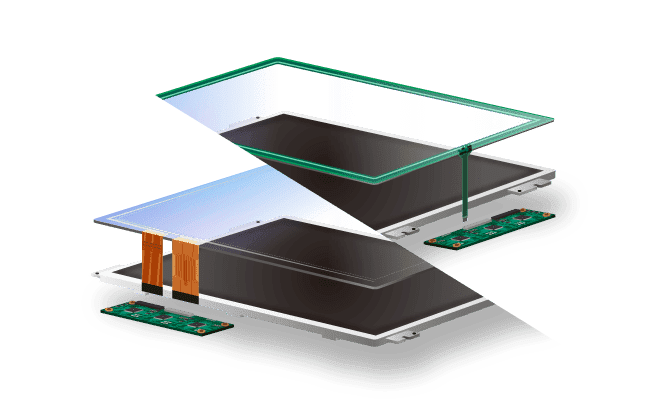

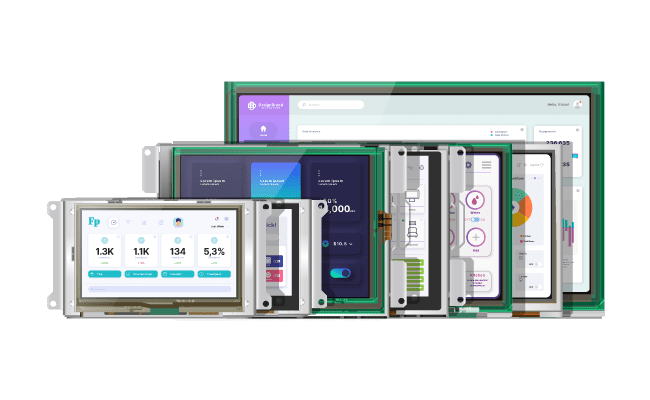

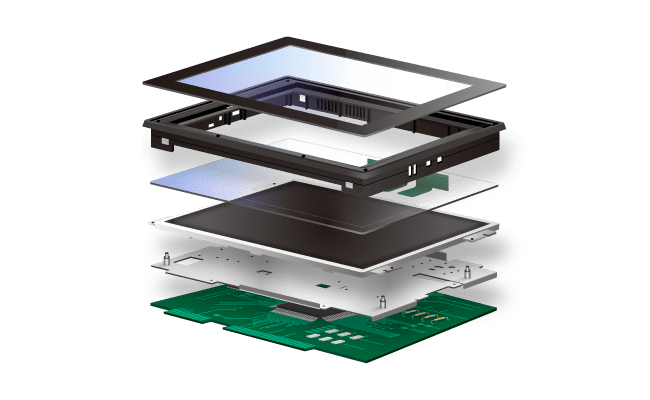

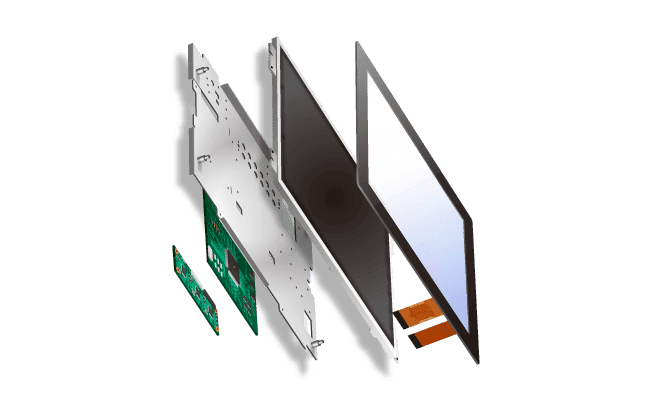

Registered Scope: Design, Development, and Manufacture of Touch Screens

Offices: Shirakawa Factory, Iwaki Factory, Tokyo Office, Osaka Office, Nagoya Office

Registered Scope: The manufacture of touch panel

Office: DMC Indonesia Factory

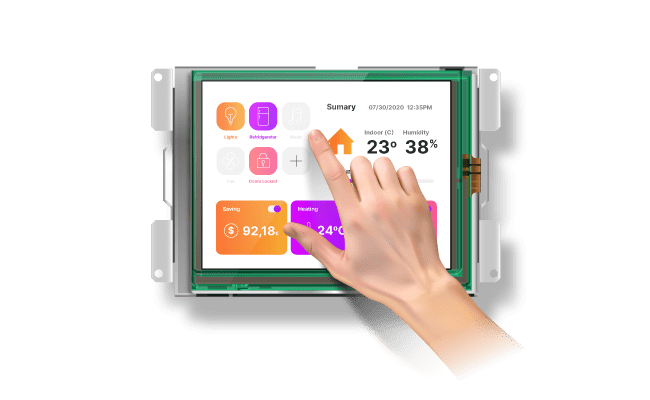

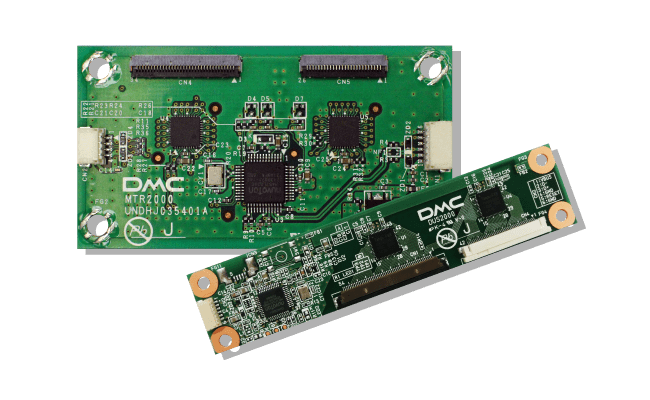

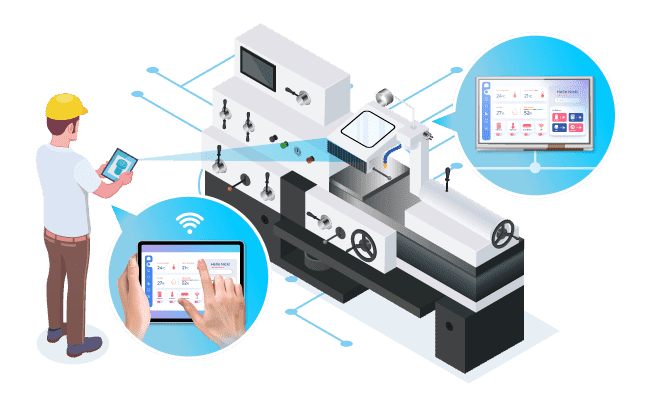

Registered Scope: Planning, development, manufacturing and maintenance services of embedded equipment for industrial equipment etc.

Department Scope: Unit Engineering Department, Izumi Factory, Domestic Sales Department

Offices: Izumi Factory, Tokyo Office, Osaka Office, Nagoya Office, Osaka Technology Center

Quality management system

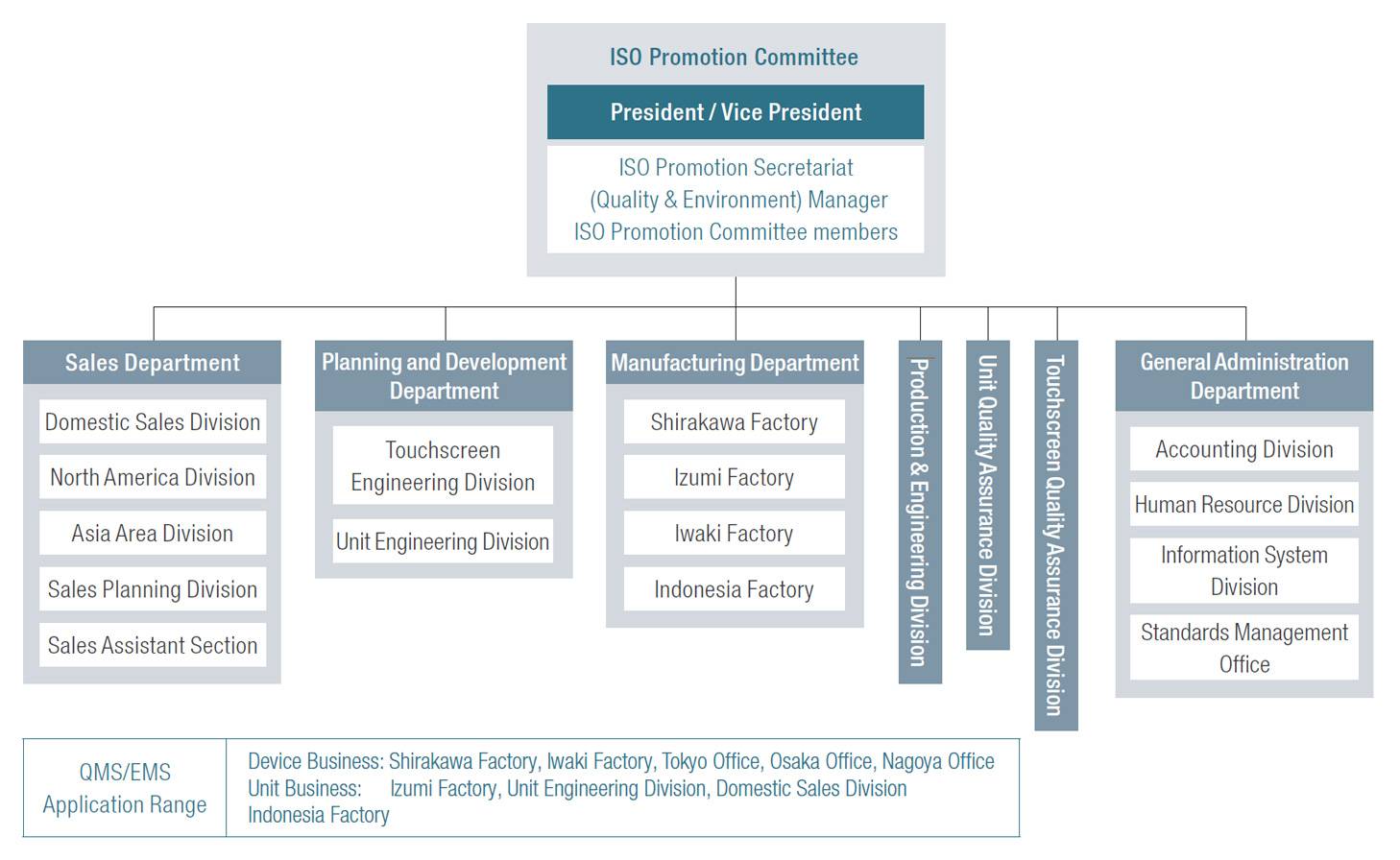

DMC has built a robust quality assurance system to deliver highquality products and services that meet customer expectations. We conduct yearly management reviews to examine and evaluate the state of our quality management system in line with our quality policy as well as quality targets to implement actions for improvement. And yearly audits are conducted by certified internal auditors. DMC shares progress in target achievement and product quality issues at Production quality meetings (Unit Business*) held once per month, and promotes the PDCA cycle to ensure that all employees understand quality policy and achieve ISO targets established by each division. In addition, ISO certification has been obtained for both the Device Business and Unit Business, and the Iwaki Factory obtained ISO 9001 certification in August 2023, maintaining our 100% certification coverage rate at our production sites.

* Unit Business: Plans, develops, manufactures, and repairs embedded devices for industrial equipment

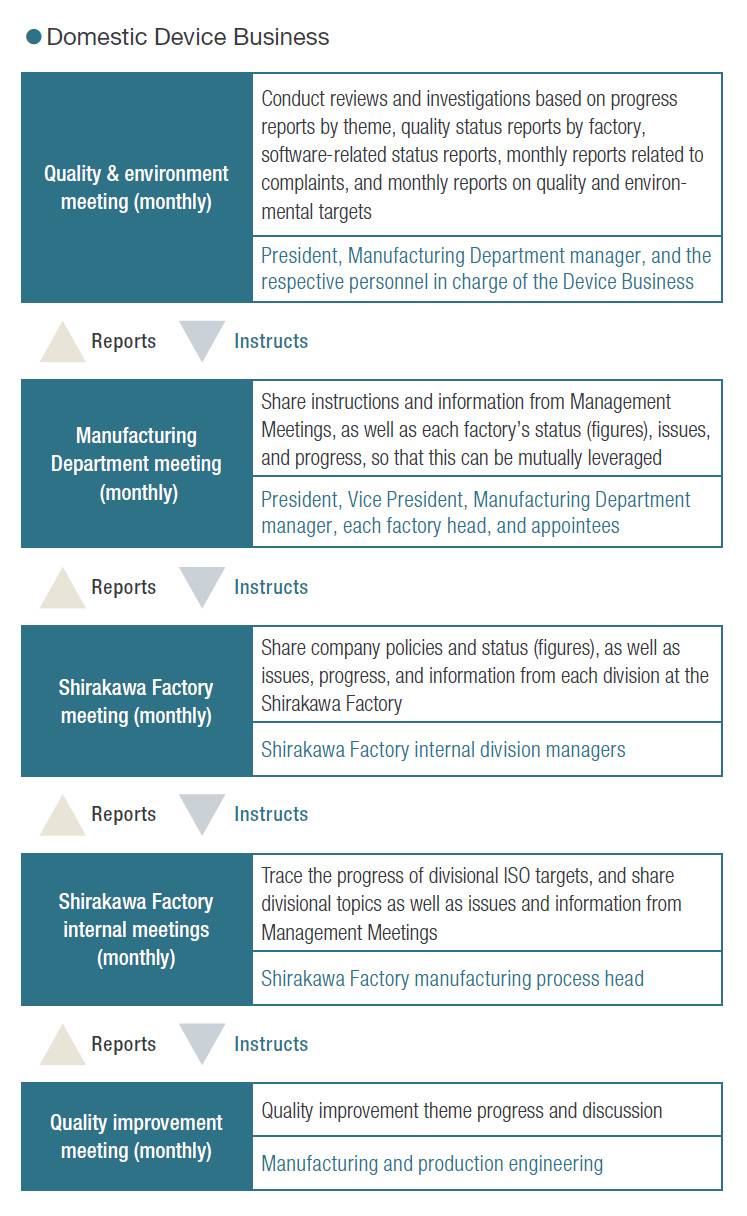

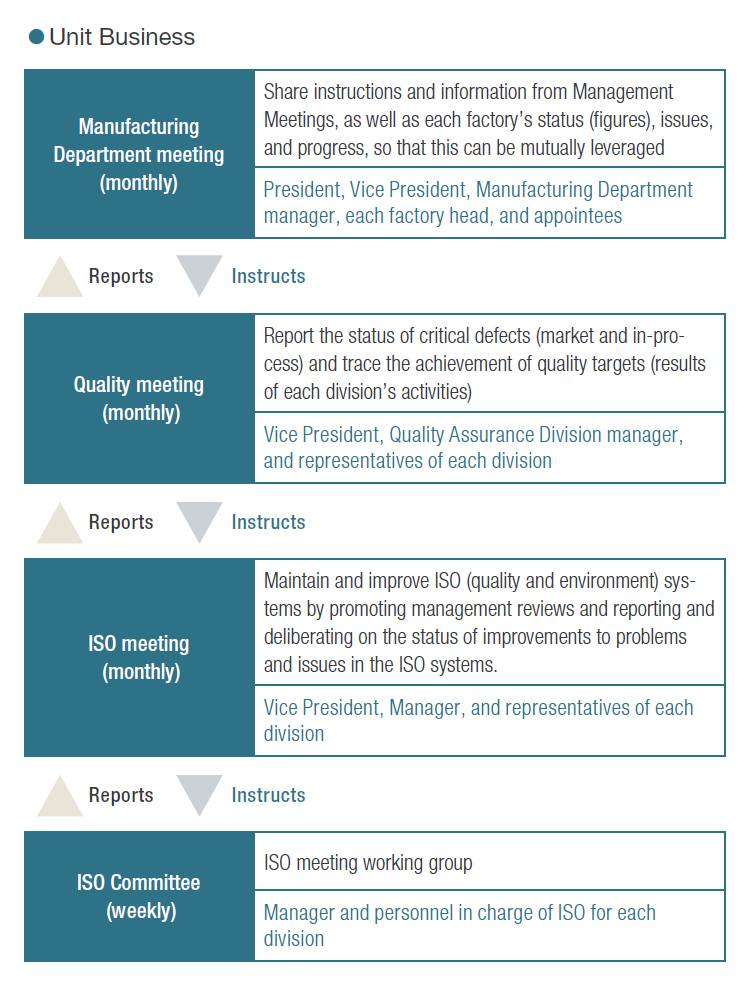

Quality & Environmental Management System Diagram

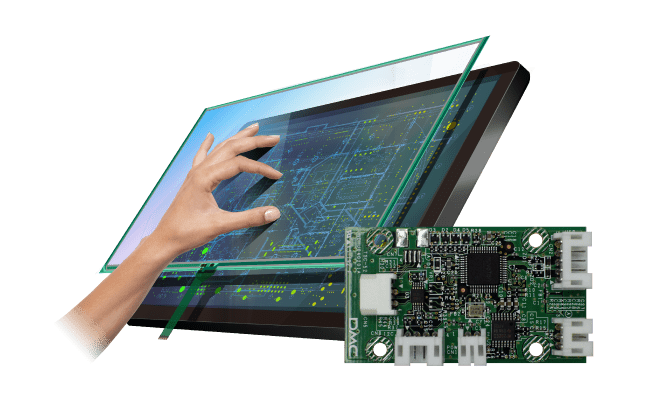

Approaches to Product Quality Improvement

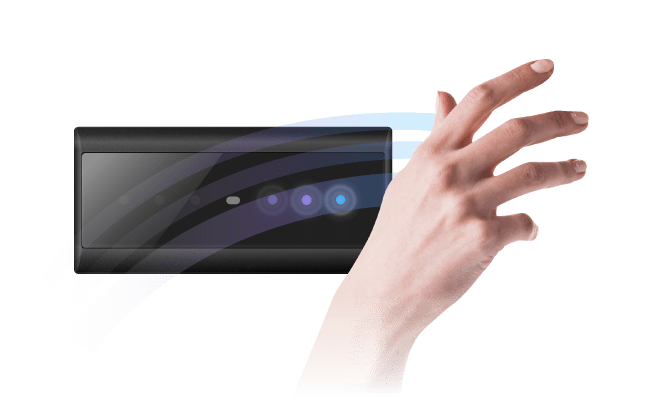

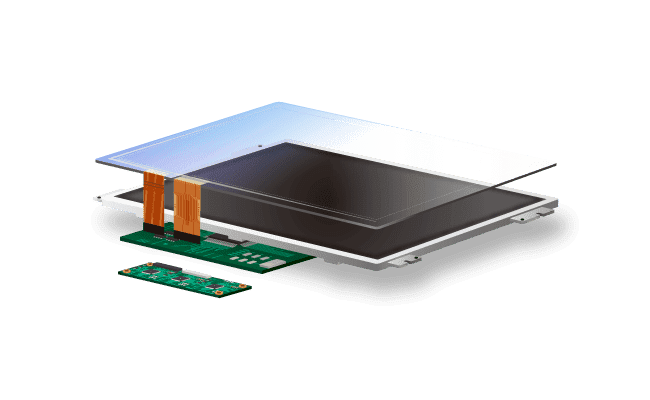

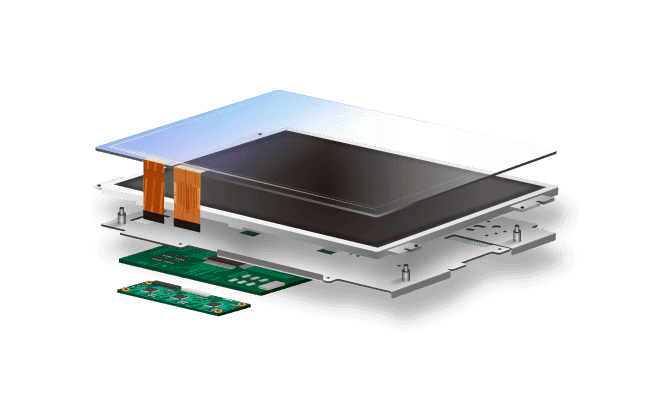

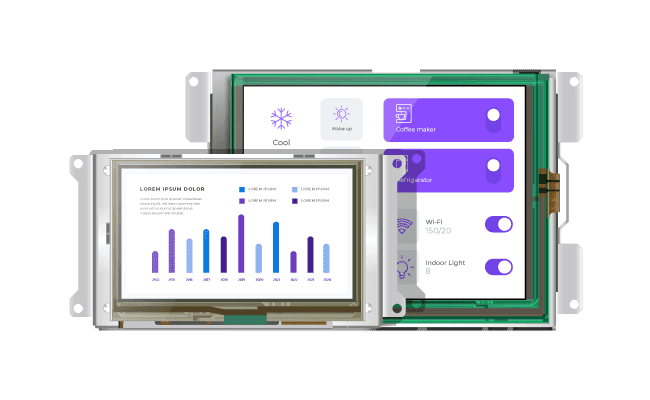

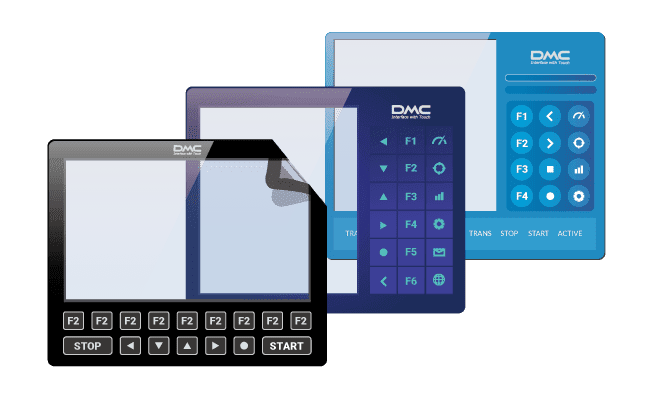

Our group leverages its technology, knowhow, and systems that can precisely respond to the sophisticated and diverse quality requirements of our customers and provide even higher-quality products.

New Product Strategy Meeting

Product strategy meetings are held monthly with the President, Vice President and representatives from the Planning and Development, Sales, and Manufacturing departments, in a system that allows us to analyze customer needs and reflect them in our products. In FY2024, we discussed new manufacturing methods for touchscreens and next-generation unit products (touchscreen application), and advanced the production of environmentally conscious touchscreens and the development of new unit products tailored to current trends and customer demands.

Quality Improvement Activities

With the aim of improving production technology and productivity, we work to ensure productivity improvement and stable quality by conducting initiatives at the manufacturing site, and by promoting quality activities and the standardization of production processes through complaint handling. Regarding these, related departments implement initiatives by topic and report to the next meeting with important topics communicated down as instructions from the higher-level meeting.

Communication between Engineering Staff and Customers

It is important for us to accurately understand customer requests and consider detailed specifications for products. Therefore, personnel in charge of engineering visit customers with the personnel in charge of sales to have direct communication with customers.

Quality Assurance Patrols

In FY2024, we achieved a 62% year-over-year reduction in loss due to complaints (with a 35% decrease in targeted sales compared to the previous year). Many of these complaints stemmed from legacy production issues, which we addressed individually to meet targets. To prevent recurrence, we address root causes through design-stage reviews and improvements across production processes. All customer complaints are documented internally via claim reports, and a final corrective action report is submitted to the customer for closure. Highpriority issues are continuously identified as critical themes at Quality and Environment Meetings (Device Business) and at Quality Meetings (Unit Business). In FY2024, there were no serious product accidents, such as major injury or equipment damage, involving customers or within the company.

*QA: Conveyed as instructions by the Quality Assurance (QA) body. It is important for us to accurately understand customer requests and consider detailed specifications for products. Therefore, personnel in charge of engineering visit customers with the personnel in charge of sales to have direct communication with customers.

Improvement of Customer Satisfaction

Once a year, our Sales Division conducts a customer satisfaction survey for each of our device and unit businesses. We distribute surveys to major sales agents and others to gauge customer satisfaction. The customer satisfaction surveys consist of 30 items for the Device Business in 7 categories (sales, sales promotion, delivery, quality, technical capability, competitiveness, and other), and 30 items for the Unit Business in 8 categories (quality, complaints, repairs, delivery dates, original products, proposals, sales/operations, and order/discipline).

The aggregate results are shared with relevant divisions within the company as customer feedback. This allows us to identify issues and improve products with the goal of maintaining customer trust. In FY2024 we surveyed 11 major sales agents for the Device Business (10 domestic and 1 overseas) and 9 major customers for the Unit Business (domestic only). In the Device Business, customer evaluations regarding cost and quality were particularly strict. We will continue refining standards and improving processes. While the Unit Business generally maintained satisfaction levels, some customer requests were not fully met and will be addressed moving forward.

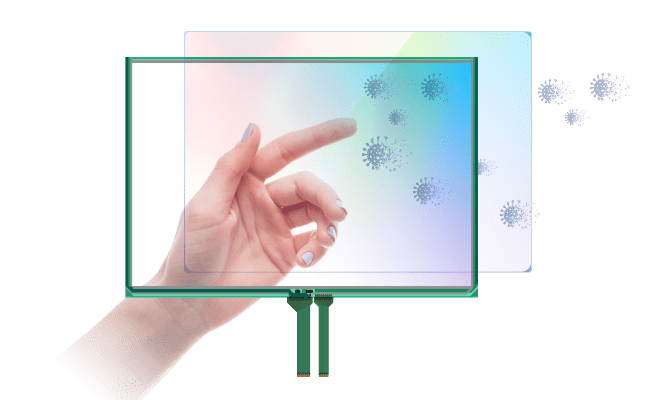

Ensuring Product Safety

Proper Chemical Substances Management

DMC performs proper chemical substances management from design to disposal to ensure the safety of our products. Our Initiatives are as follows.

Compliance with Global Laws and Regulations

We use chemical substances for our products in accordance with the laws and regulations specified by each country and promote the development of products that do not use hazardous substances that may affect people and the environment.

SDS Acquisition and Utilization

We obtain a Safety Data Sheet (SDS) that describes the danger and toxicity, and precautions of chemical substances and raw ingredients containing specific chemical substances to ensure safe handling until disposal. The division in charge of chemical substance management keeps up-to-date with the latest information on revisions to various laws and regulations regarding chemical substances and focuses on appropriate responses. With regard to chemical substance management and inquiries from customers, the Quality Assurance Division is in charge of touchscreen products, and the Standards Management Office is in charge of unit products. External specialist companies are also utilized as necessary for investigation and response regarding hazardous materials.

Product Safety Design

In each process of development, design, and manufacturing, we take measures to ensure the safety of our products during their use. In the touch panel business, we have introduced the use of scribing machines in the development, design, and manufacturing processes, which results in the prevention of glass plate edge breakage and thus injury, ensuring safety in the use of our products.

Hazardous Substances in Standard ProductsTraining on Quality

In order to continue to create products with quality and safety that satisfy our customers, training and workshops take place in each division throughout the year. In FY2024, to address the increased amount of claim losses, we focused on investigating and addressing the root causes of defects, reviewing process operations, and providing training on defect resolution.