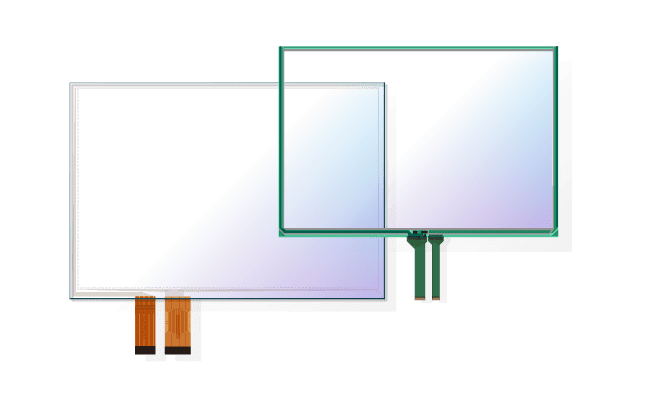

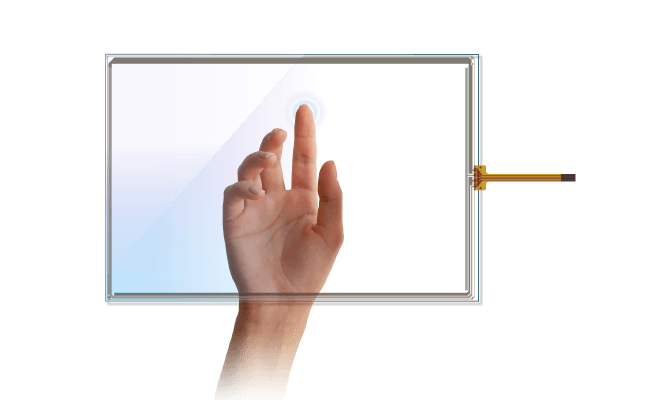

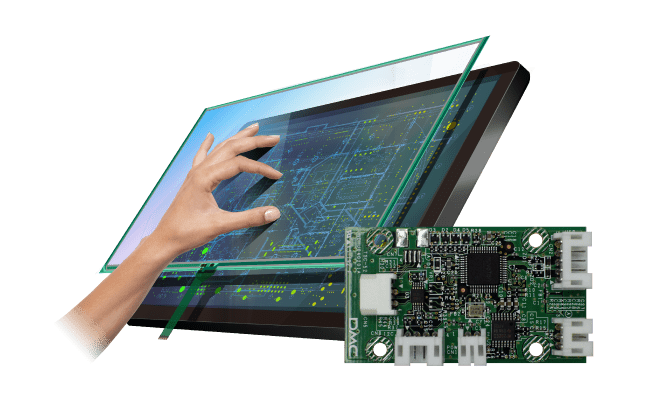

Thick or toughened glass, such as 5 mm, can be used to provide touchacreens with high strength against external violence.

More transparent than glass & can be cut & drilled. Half as light as glass, with high resistance to breakage & flexibility.

Low-cost & scratch-resistant, with a certain degree of durability. Glass up to 5 mm thick can be affixed.

Three to five times stronger than ordinary glass. It is more scratch-resistant than glass & is the most durable of all other materials.

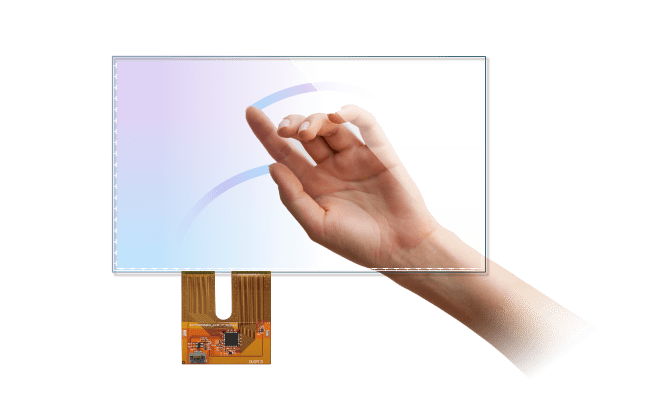

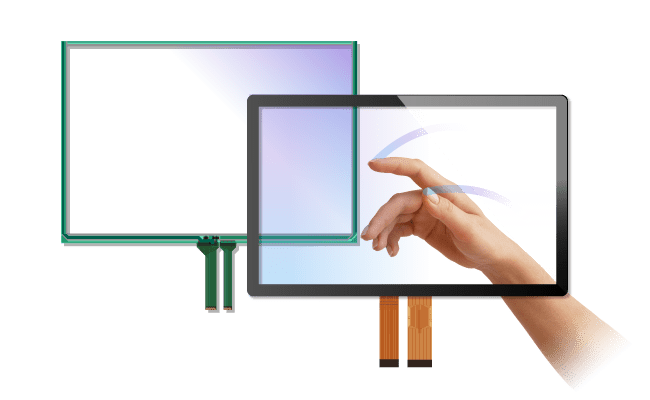

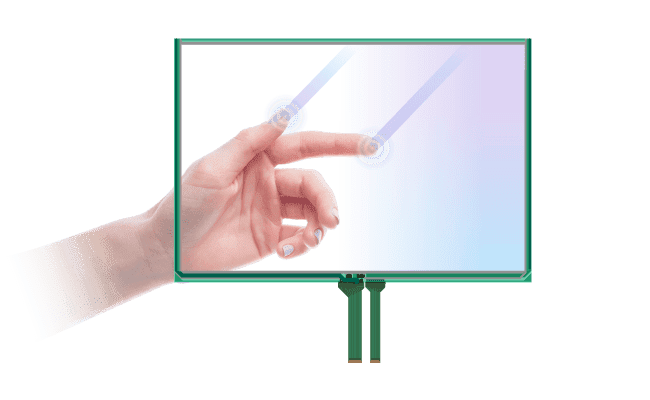

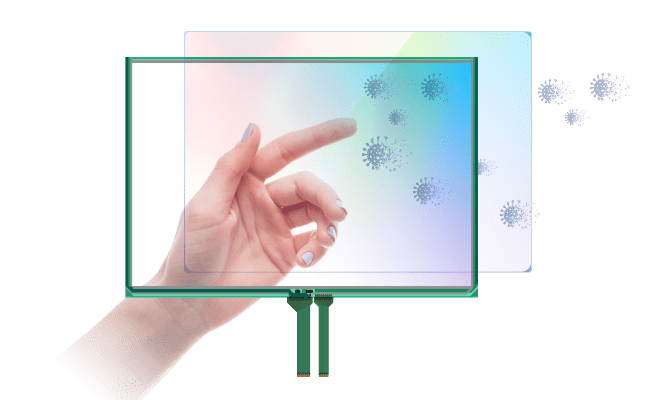

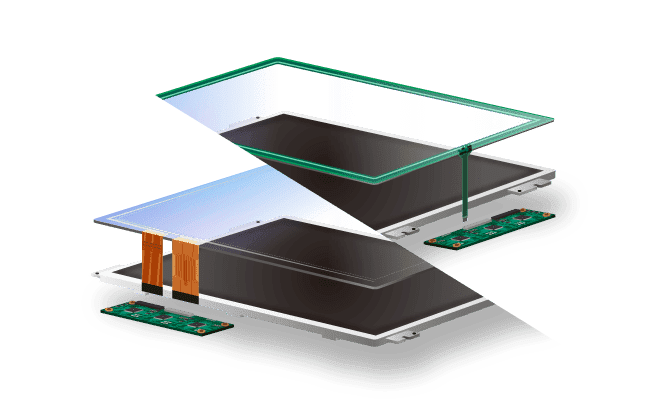

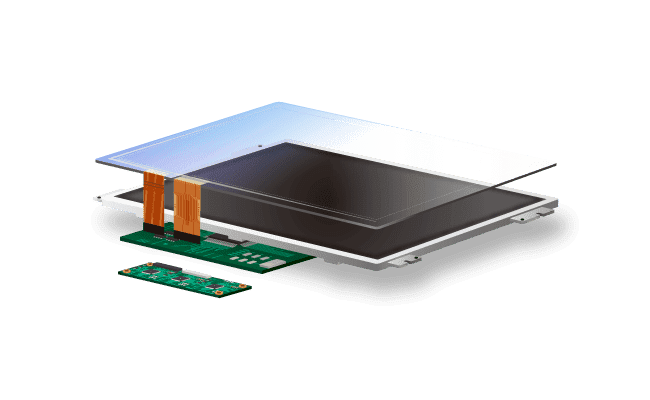

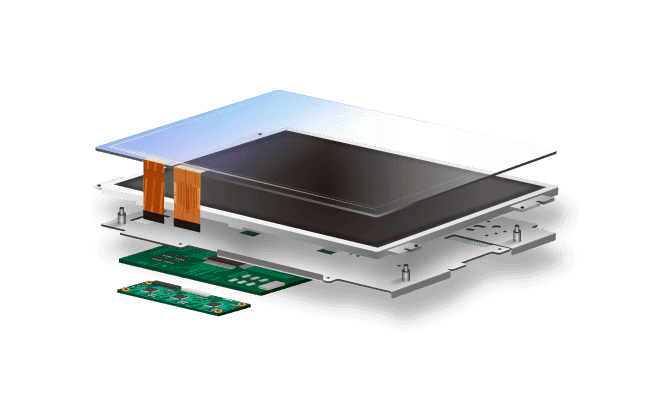

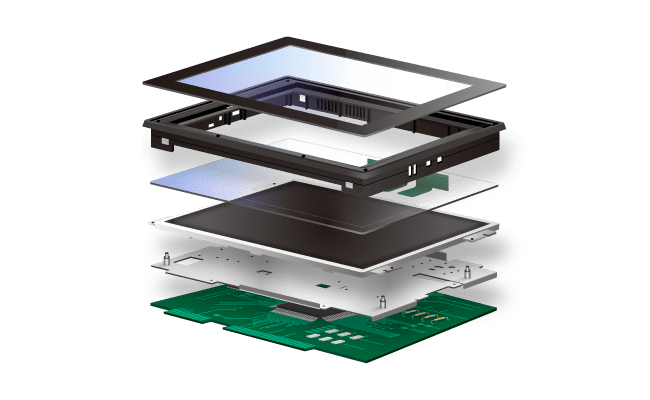

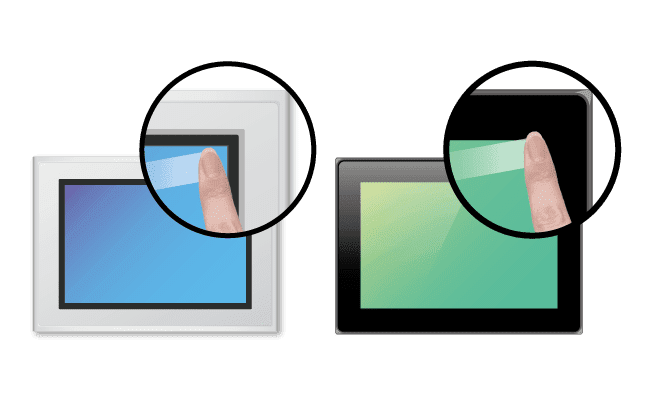

When the cover glass is attached, the bezel is no longer uneven & the screen can be touched firmly in all corners. The cover glass also repels moisture & oil & does not allow dirt to penetrate. If it gets dirty, just wipe it off. Easy to clean.

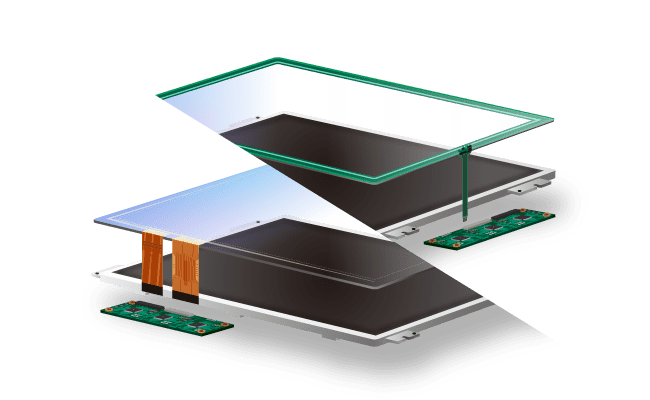

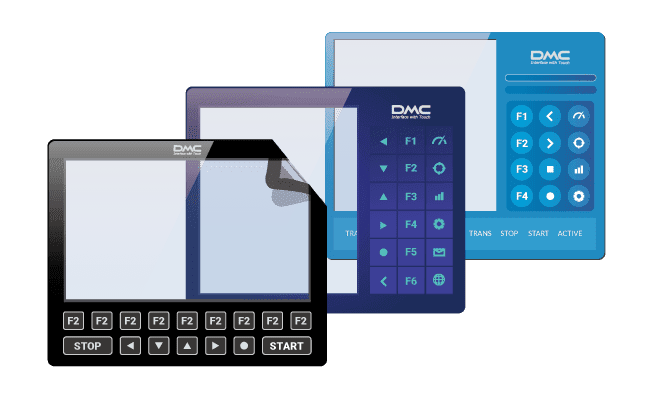

Colours can be printed on various shapes. Colour schemes can be created to match the customer's product colours. In addition to silk printing, multicolour printing is of course possible. Complex patterns & logos can also be printed.

This printing method uses a printing plate to transfer the ink. As a printing plate is required for each colour & the cost of multiple colours increases, this method is best suited to simple designs with a small number of colours.

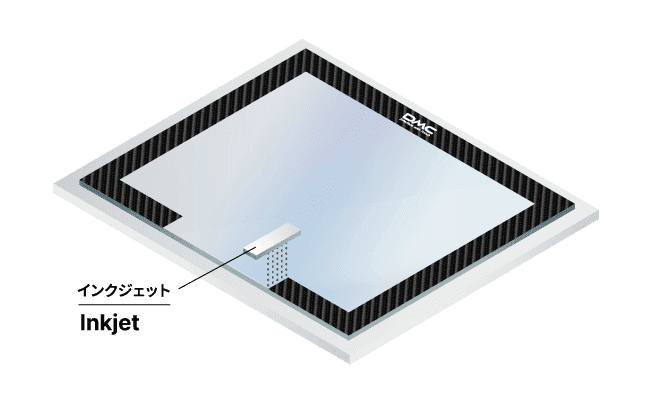

This printing method involves spraying ink onto glass. The cost remains the same even if the number of colours is increased, & high-definition, complex designs can be handled.

Inkjet printing can also faithfully reproduce elaborately designed logos. Corporate & brand images are not compromised.

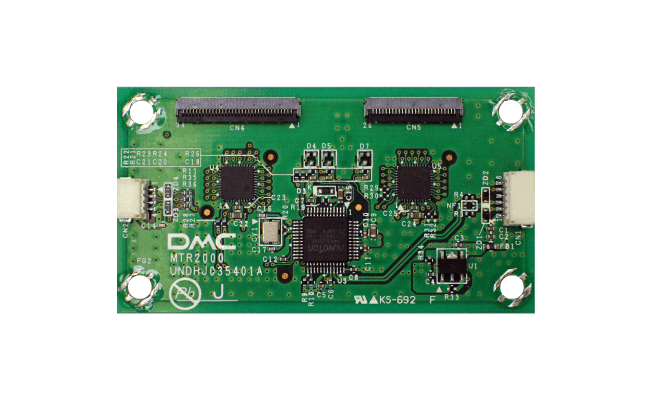

What are the key points to make Cover-Glass?

Customising glass is an essential service for creating originals for various environments, such as chemically strengthened, decorated/surfaced/externally processed glass, but the challenge is that it involves conditions that must be met, such as development time, cost & MOQ, which tends to cause mismatches in the business.

Additional new designs & specifications have to be considered, which increases the development time, cost & effort.

Additional time needs to be allocated to estimating & working costs, such as obtaining internal approval for new drawings & verification work.

As separate glass orders & printing plates need to be made, an additional period of time is required to proceed here as well.

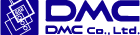

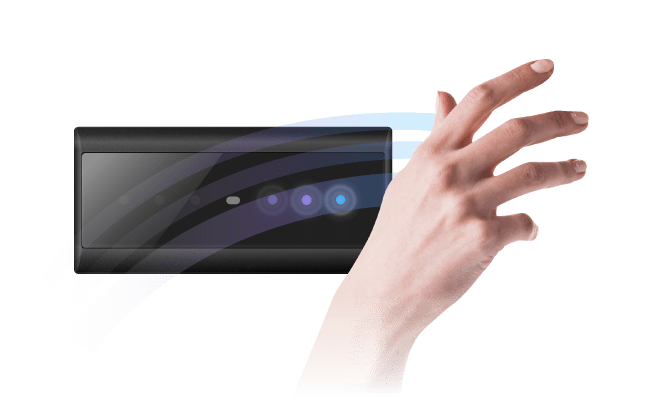

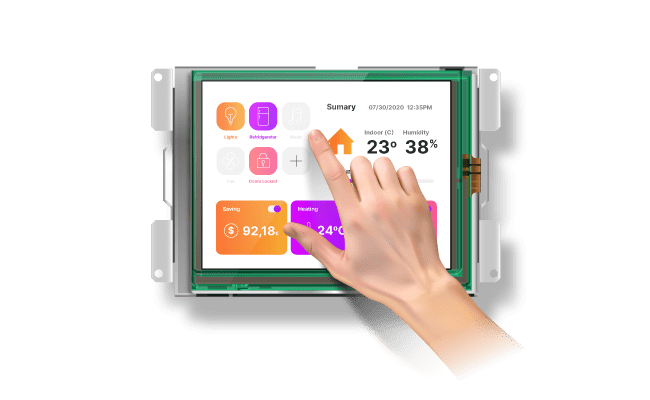

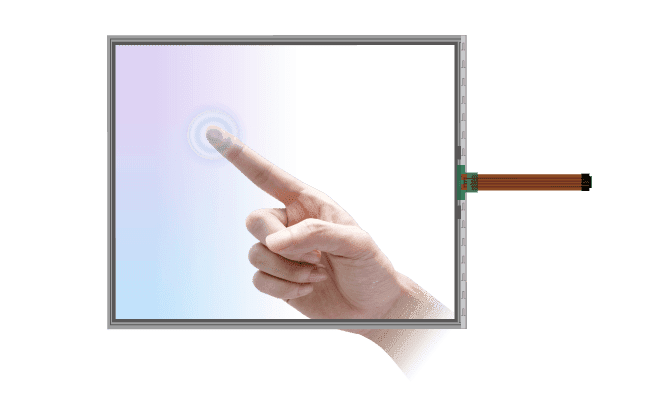

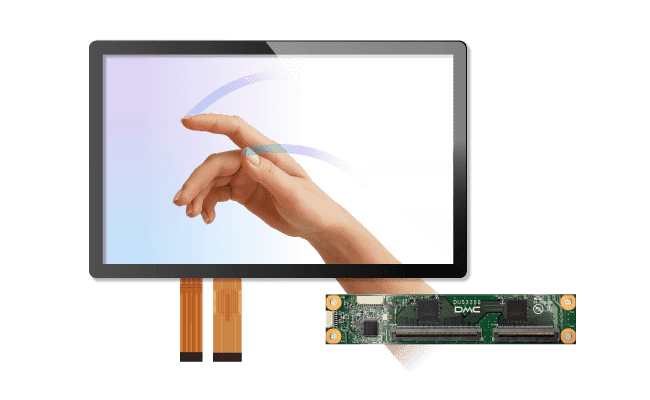

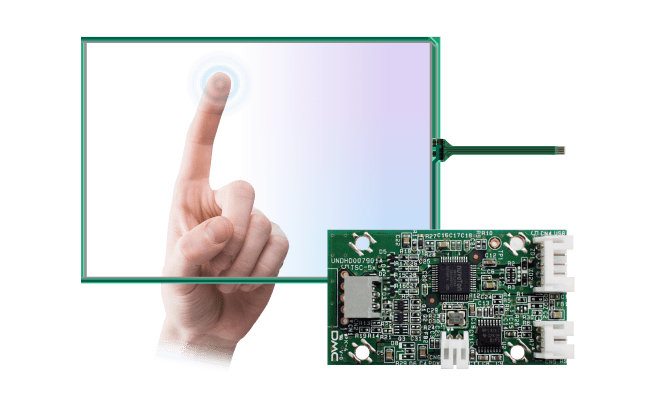

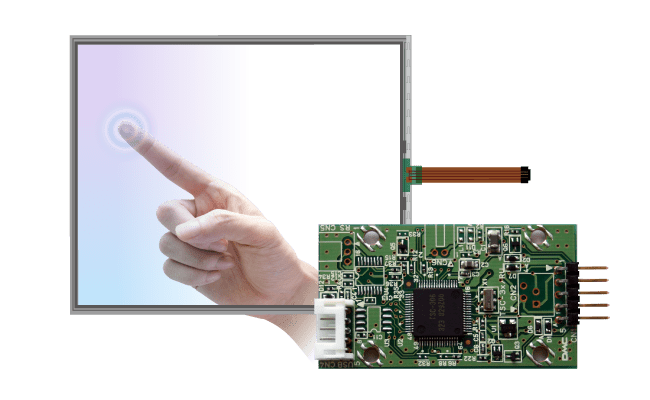

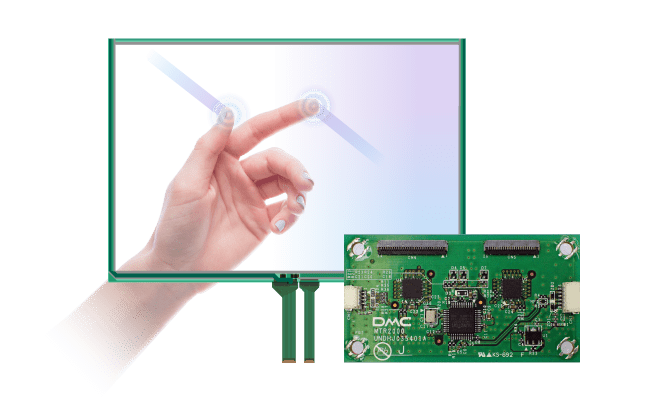

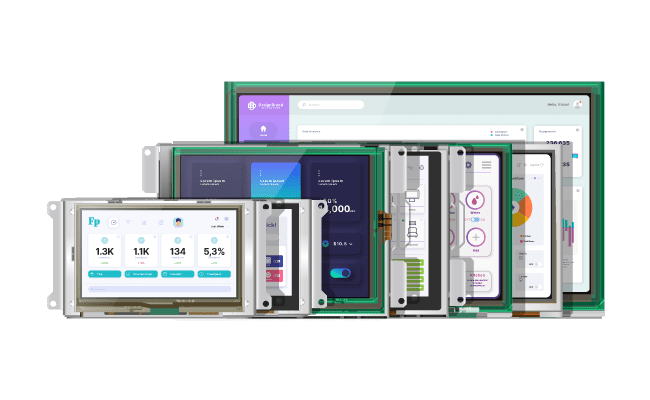

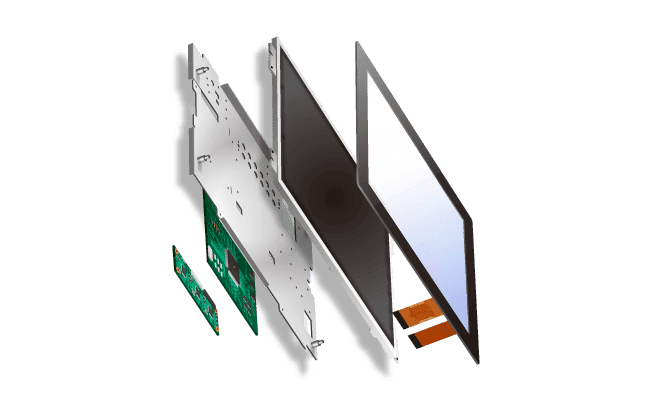

Touchacreens with Cover-Glass provided by DMC

With DMC's touchacreens with cover glass, you can choose from a standard touchacreen line-up that is always in stock, allowing you to realise the freedom of choice & improved quality that you had previously given up, in less time & at a lower price. Additional customisation as a base is also possible, which speeds up development & can be considered in conjunction with higher requirements.

The simple black-on-black framed design, which can be used with any enclosure, reduces costs but gives the product an elegant face.

Tempered glass by default. High robustness & clear visibility for protection against shocks & scratches & good appearance.

Standard product, so always kept in stock. Can be supplied immediately when required. Efficiently compresses delivery times & reduces costs.