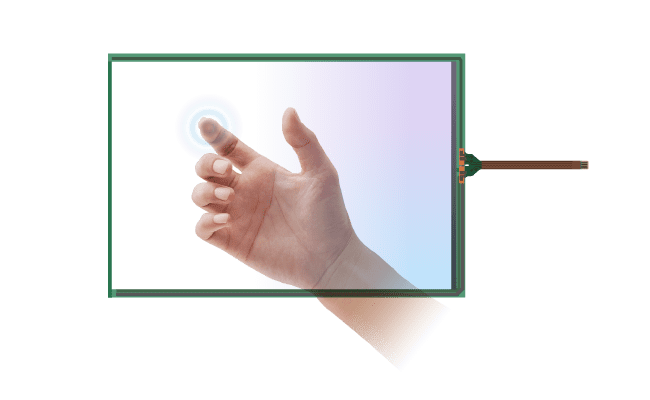

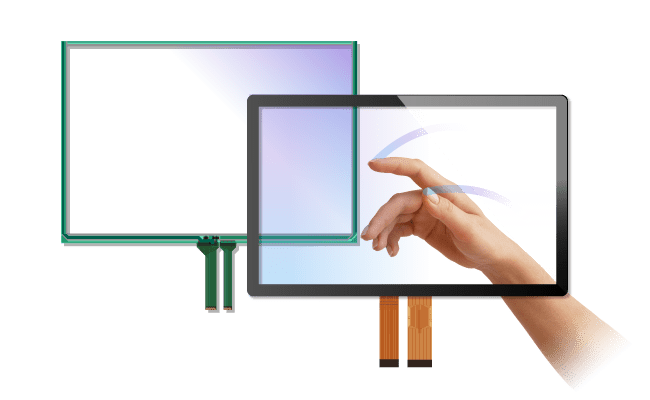

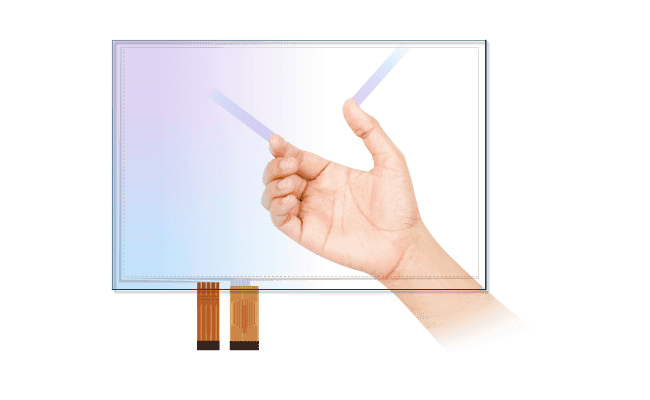

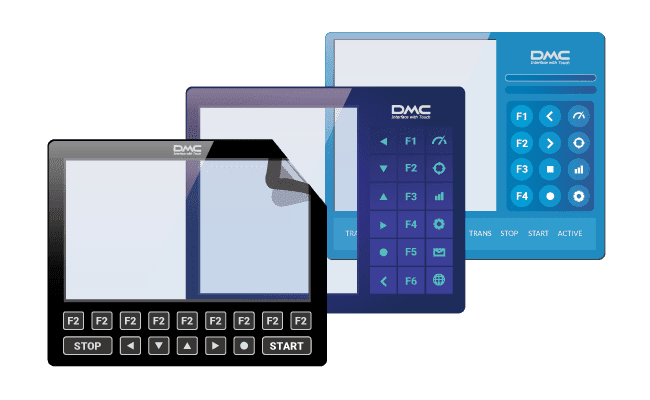

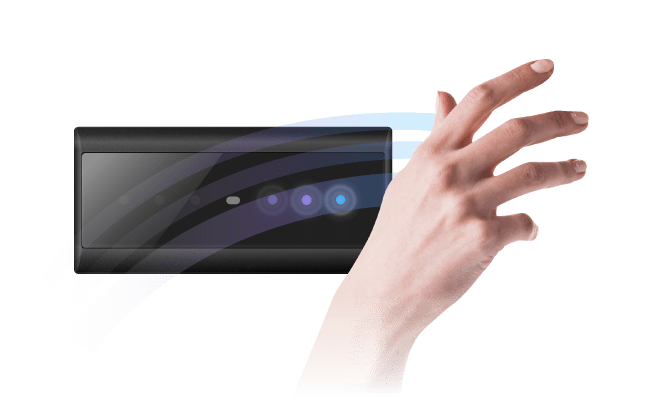

Resistive Touchscreen Features

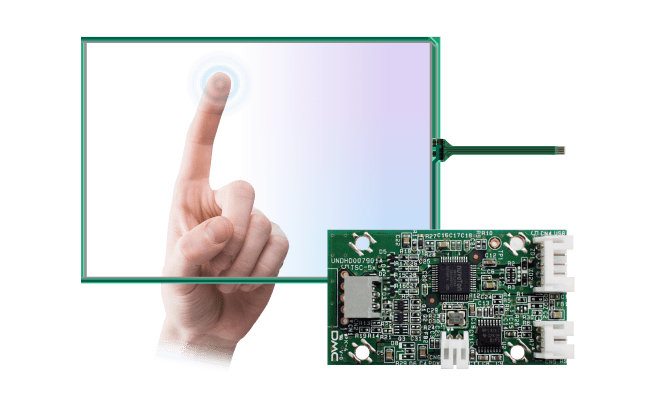

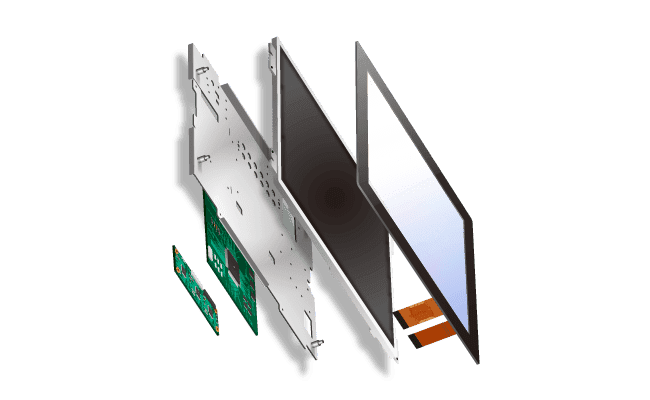

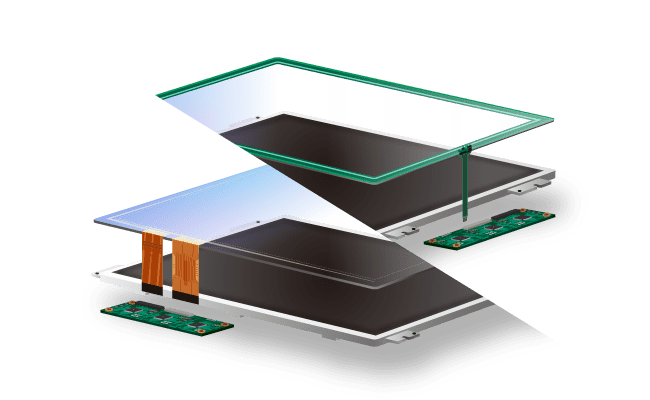

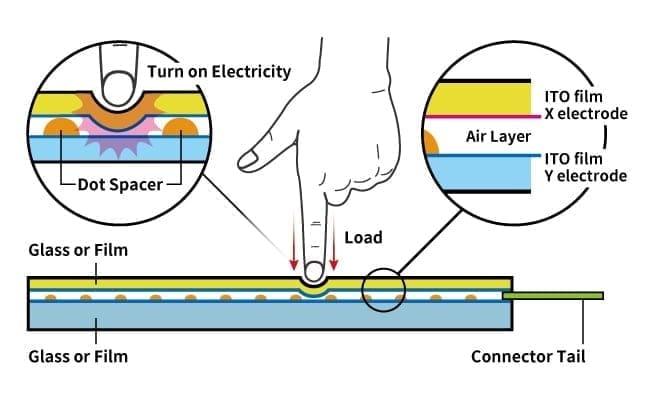

Resistive touchscreen is a method of detecting position by energizing the contact point of the electrodes (ITO film: transparent conductive film) facing each other, and is used in various devices such as ATMs at banks, ticket vending machines at stations, and especially in industrial applications as a reliable touchscreen.

-

Touchscreen system with strong popularity in industrial applications

A highly reliable touchscreen that has been used in a wide range of applications for many years.

-

The resistive film method is a system used in many industrial applications, especially in factory automation (FA). It detects the position by measuring the electrical voltage generated when two electrically conductive films (ITO: Indium Tin Oxide) touch. The position is detected by measuring the voltage generated when the conductive film (ITO: Indium Tin Oxide) is touched. It is sometimes referred to as a "pressure-sensitive" system. It has advantages such as stability, positioning accuracy, ease of installation, and low cost.

-

Resistive Touchscreen Characteristics

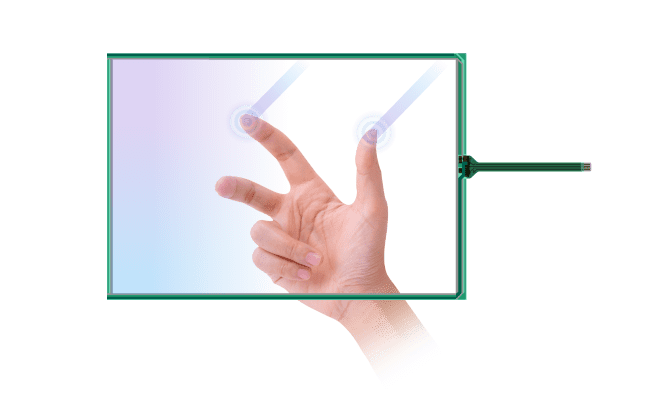

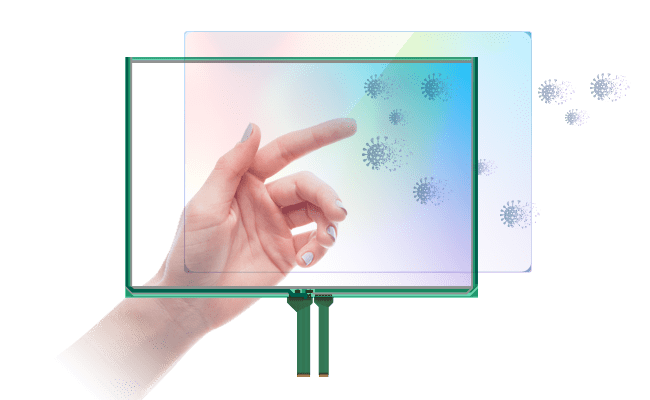

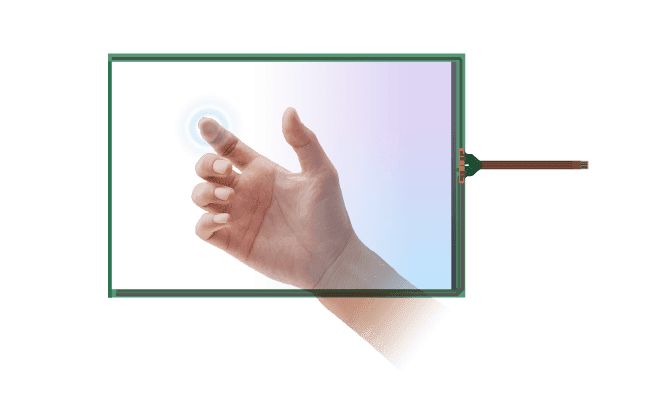

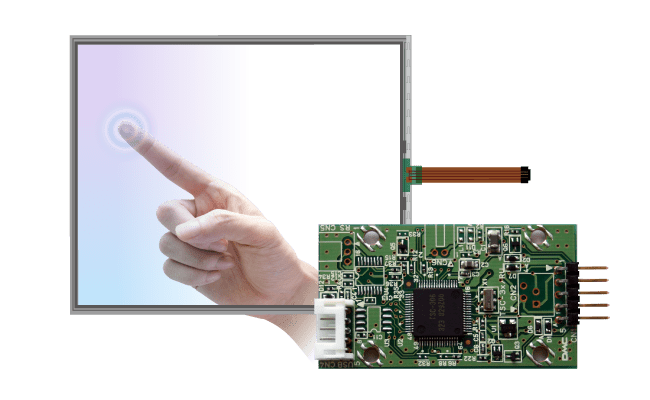

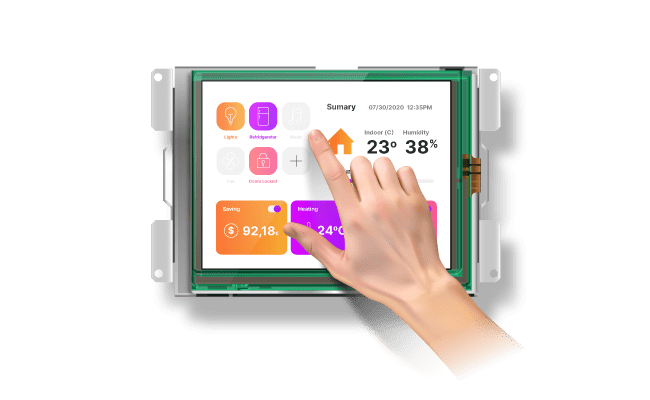

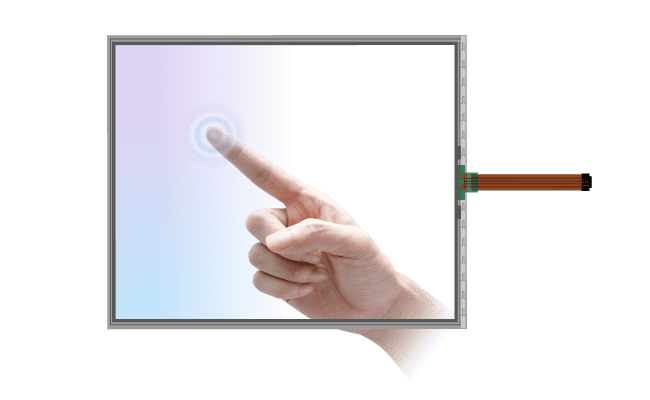

Touchscreen that can be operated while wearing gloves

-

By applying pressure with a hand or pen to a picture, icon, menu, or other area displayed on the screen, the system senses the information of the screen position touched. The external device can perform the appropriate action required by the operator based on the position information on the screen. Because of its pressure-sensitive nature, it can be operated while wearing gloves, and this resistive system is used in many machines and operations where mishandling is not allowed, as well as in general screen operations in the city.

Principle of operation of Resistive Touchscreen

-

-

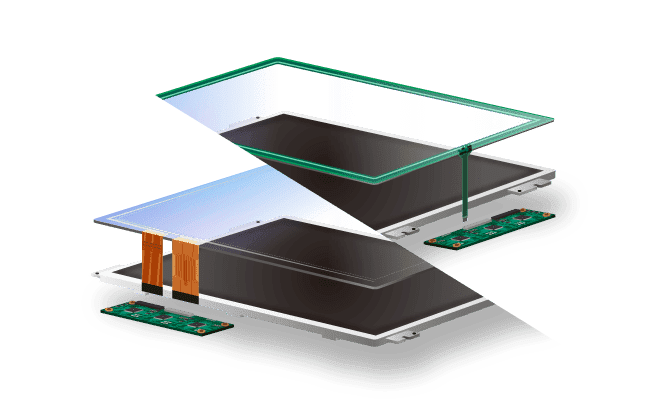

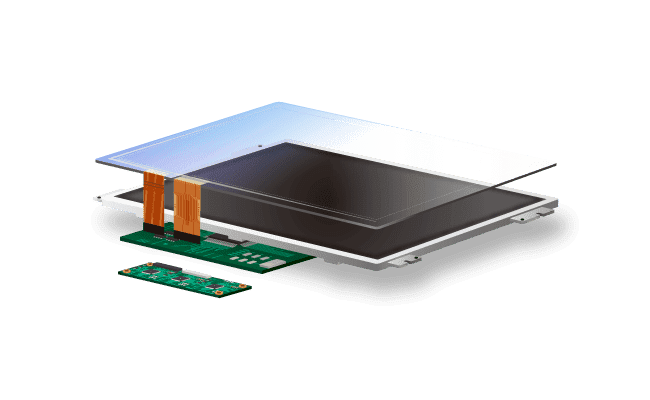

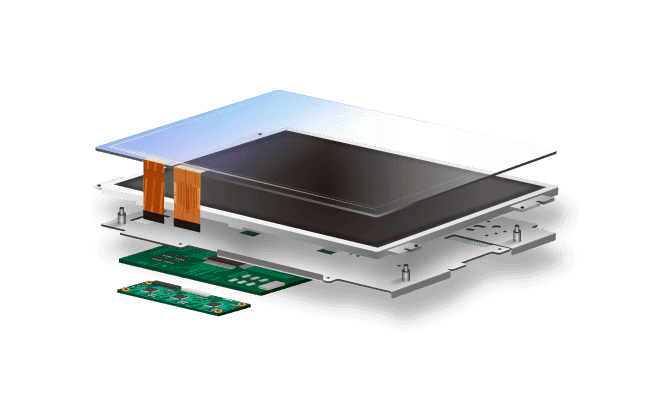

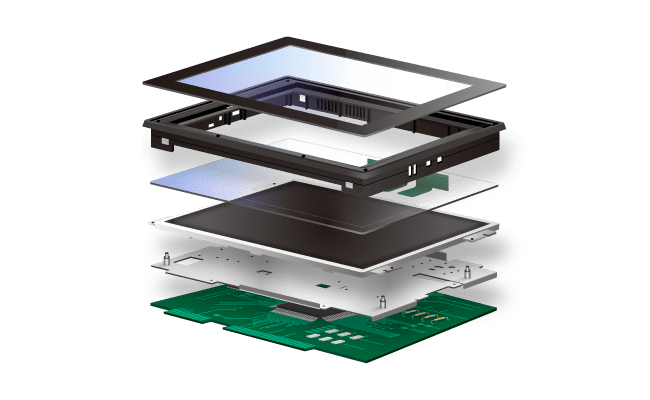

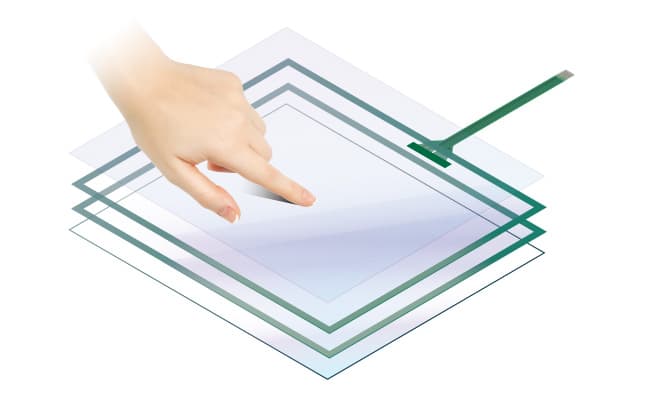

Detects input position by load

When the panel is pressed, the upper substrate flexes and the upper and lower ITO electrodes (X/Y electrodes) contact and conduct each other to detect the input.

An insulator (dot spacer) is placed between the upper and lower ITO electrodes to prevent short-circuit between the electrodes when no input is made. Resistive touchscreens can be roughly divided into two types: analog type and digital (matrix) type.

Analog and digital types

Analog single touch type

-

-

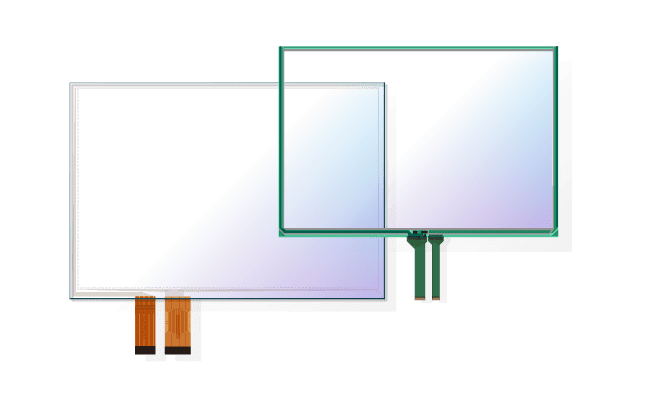

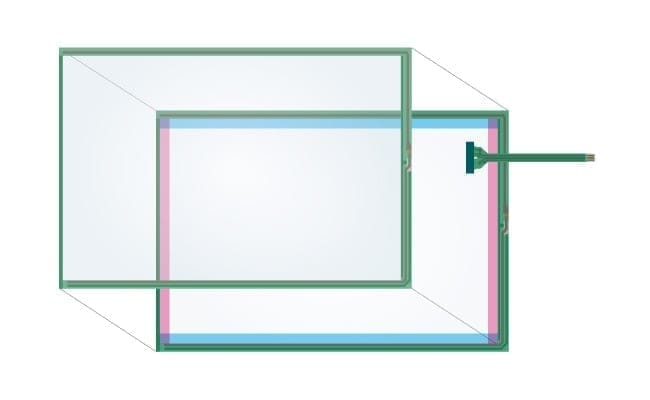

Transparent electrodes are formed on one side of both the top and bottom of the device, and one side constitutes the X-coordinate circuit and the other side the Y-coordinate circuit. The voltage of the touched position is detected.

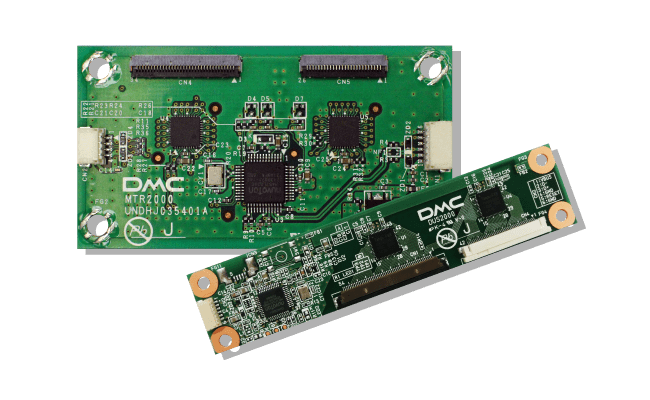

There are three types of analog systems: 4-wire, 5-wire, and 8-wire, etc. DMC mainly uses the 4-wire system as the standard, and the 5-wire system for the high durability models.

-

-

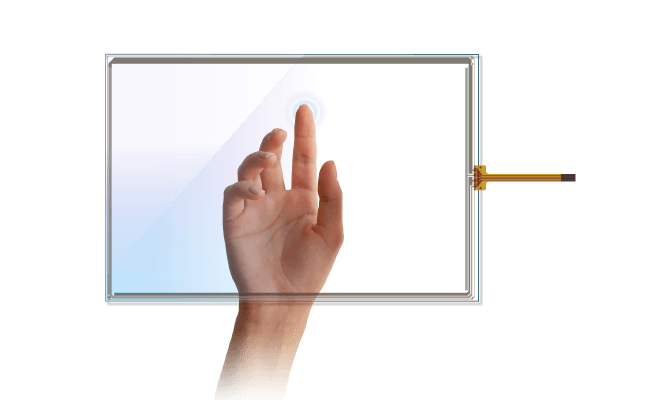

4-wire system (single touch)

The DMC detects the position of the X and Y axes using parallel X and Y electrodes formed on the upper and lower substrates, respectively.

-

-

5-wire system (single touch)

The 4-wire system has the X-axis on the upper board and the Y-axis on the lower board, while the 5-wire system has the XY-axis position detection on the lower board. The 5-wire system concentrates the XY-axis position detection on the lower substrate. Therefore, even if the ITO film on the upper substrate is scratched, the position detection function is not impaired except for the scratched area. In the 5-wire system, voltage detection is performed by the upper electrode, and position detection is performed by distributing the wiring for both X and Y axes to the lower electrode. Translated with www.DeepL.com/Translator (free version)

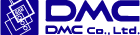

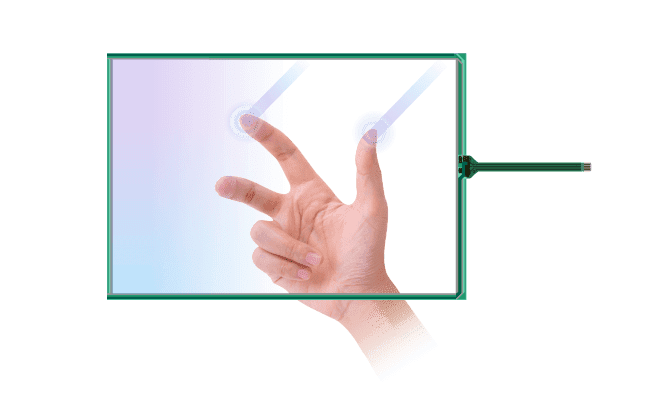

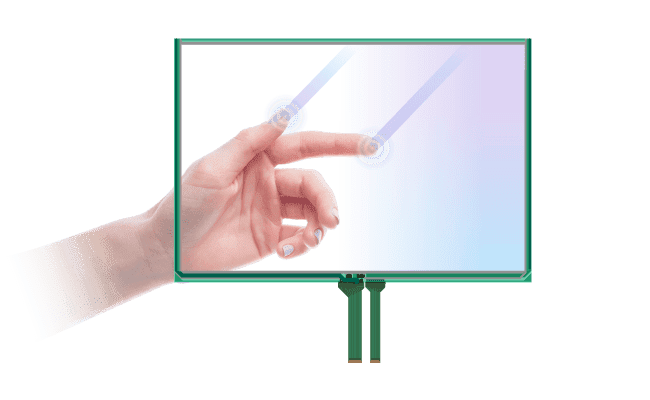

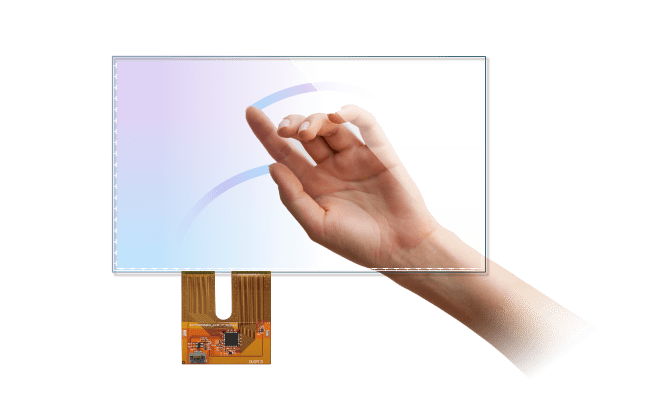

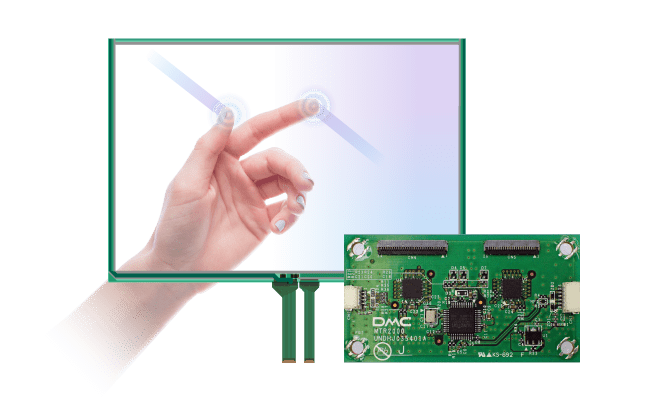

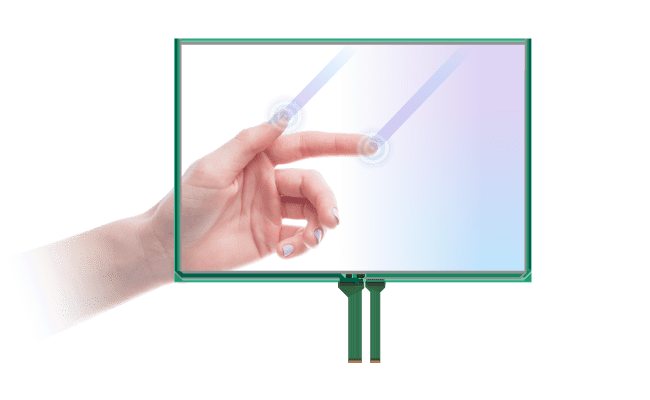

Analog multi-touch type

-

-

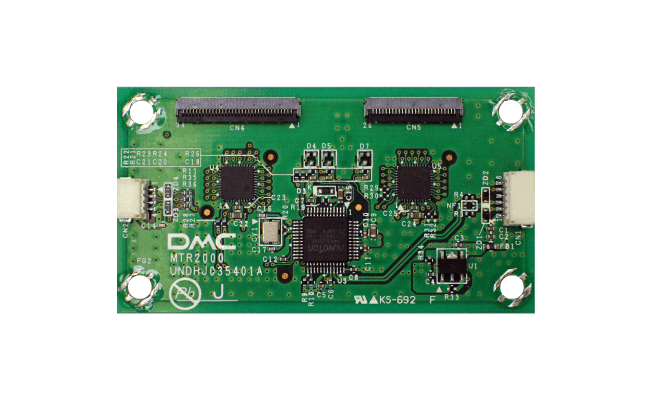

DMC original touchscreen based on 4-wire resistive film with additional multi-touch function. The basic structure is the same as the 4-wire resistive single touch type. In multi-touch, the detection surface is divided into cells to virtually configure multiple touchscreens to realize multi-touch.

-

-

4-wire system (multi-touch)

Based on the 4-wire resistive film method, the sensor is divided into cells, each of which is independent. Each divided cell functions as a touchscreen, enabling simultaneous input (multi-touch) between different cells. In principle, it can be recognized in the same way as an ordinary 4-wire touchscreen. Simultaneous detection of multiple points is possible. By reducing the operating load, gesture operation like capacitance is possible.

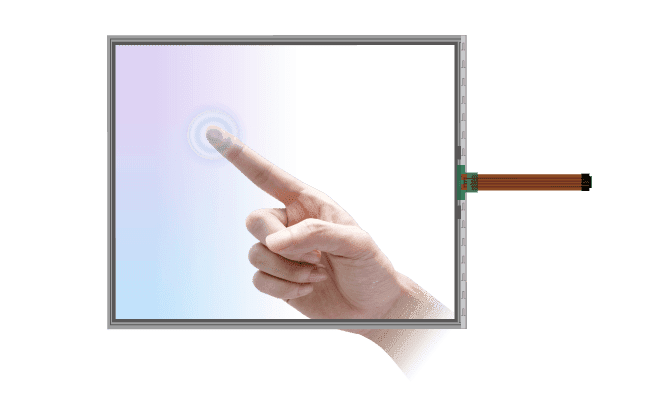

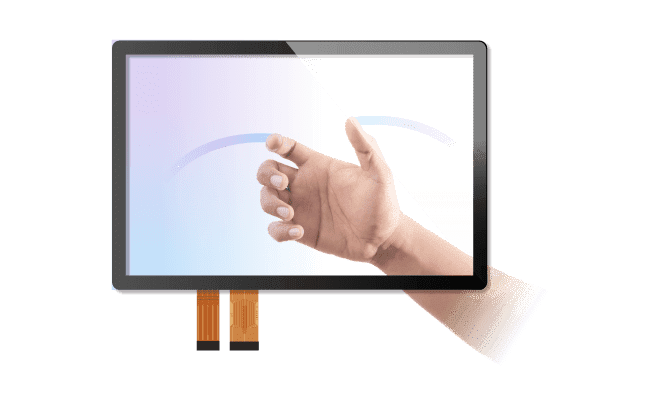

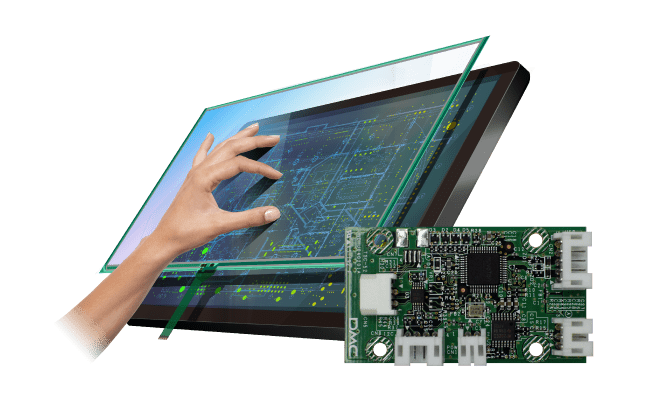

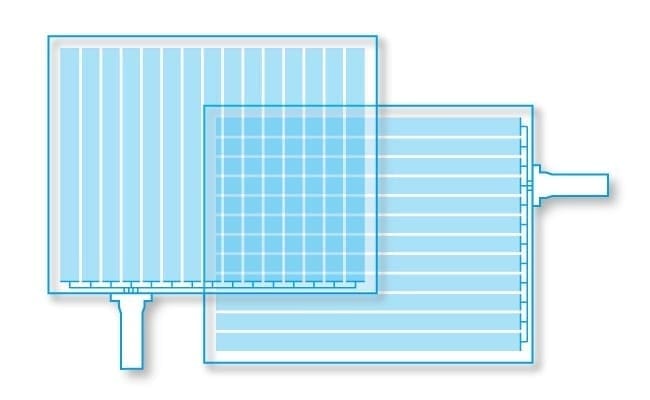

Digital (matrix) type

-

-

Two strip-shaped electrodes, X and Y, are formed at the top and bottom, respectively, alternately facing each other and intersecting at right angles. Wires are placed from one side of each electrode to detect the point where there is continuity in the X and Y coordinates when touched.