Current status of touchscreen display products

The display monitors we use in our everyday lives. PCs began to spread and were used in offices in the 1980s. In the beginning, analogue displays using CRTs (cathode ray tubes) were common and many were black and white; by the mid-1980s, laptop PCs were widespread, and by the late 1980s, full-colour graphic displays became popular, and with the development of notebook PCs and other lightweight products, LCD displays came into use.

LCD monitors, which were still expensive, were generally designed with ostentatious bezels and enclosures, but nowadays slimmer, more design-oriented displays are becoming mainstream. The trend is for bezels to have extremely narrow frames and thin, lightweight enclosures, and this has evolved in tandem with technological developments. This is largely due to, amongst other things, the fact that colour reproduction, contrast, viewing angles and the display of fast-moving images, photos and videos have become commonplace in our daily lives.

An increasing number of today's touch-enabled displays on smartphones and tablet products are thin and compact, with virtually no bezel frame and larger screens that can still be used in the palm of the hand. Many of these slim, well-designed display products around us are intended for consumer applications. Consumer products do not face the challenging requirements of industrial applications, such as long-term supply, environmental resistance, reliability, and support. For industrial applications, it is necessary to select monitor and touch display products that are designed to operate for long periods of time and under harsh environments.

What is required for an industrial touch-monitor?

TOUCHSCREEN SOLUTION

When touch-monitor products are used in industrial applications such as factory automation, they must satisfy various requirements that consumer products cannot. For example, in industrial applications, various evaluation tests are conducted prior to adoption, and once adopted, the same product is often used for more than 10 years. The same product must have a long term stable supply. In contrast, consumer products are often replaced by new models within a few years after their release and the old models are no longer available.

Industrial applications require higher reliability and durability than their consumer counterparts because they are often operated throughout the day for long periods of time in harsh environments (24-hour operation, wide temperature range, vibration environment, dustproof and drip-proof, etc.) that are not expected in consumer applications. For example, monitors installed in a wood processing plant are subject to a dusty environment, and if dust gets into the equipment, it can cause malfunction or fire. Equipment installed in wet environments, such as food processing equipment and water-jet processing machines, can also malfunction if moisture gets inside the equipment.

Customer design and support from the manufacturer is another important factor in industrial applications. When developing a device with a touch-monitor, various technical issues such as noise interference may arise. In addition, monitor manufacturers need to meet the unique technical requirements of equipment manufacturers; for consumer products, it is difficult to deliver such individualized hardware needs.

On the other hand, as the market for smartphones, tablets, and other products with high design quality in consumer applications expands, the expectation for the same design attributes has been increasing significantly in industrial applications.

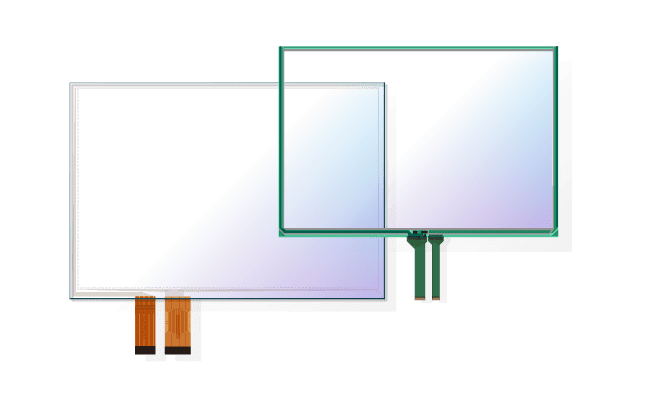

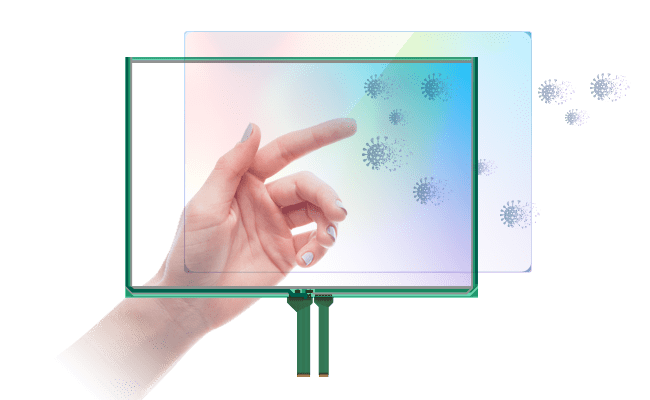

Industrial touch monitor with a contemporary design aesthetic

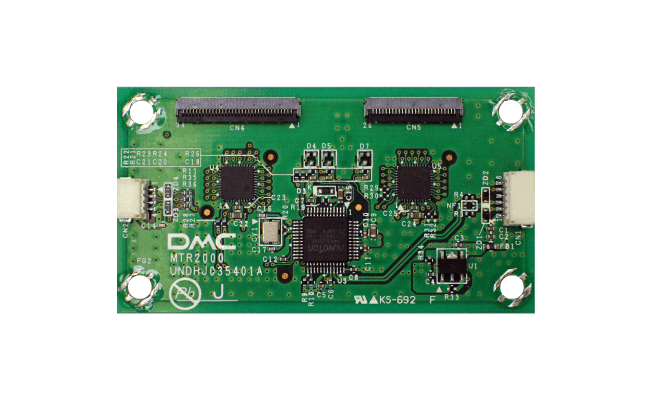

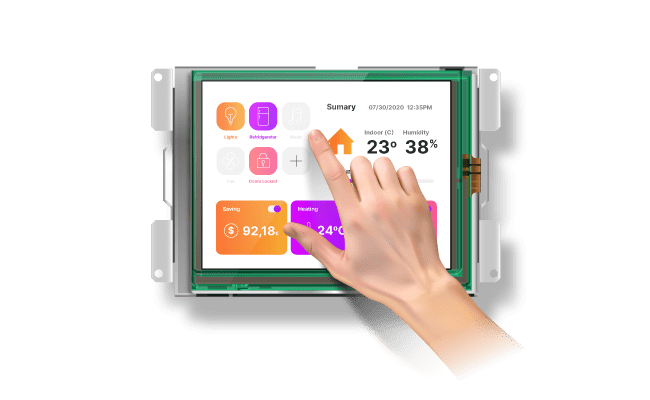

DMC and Seesaware have lined up Stylish/Smart Touch Monitors based on the concept of 'touch monitors that can be used for industrial purposes and have a good design'.This Product line includes two types of touch panels, capacitive (PCAP) and resistive, both of which support gesture operations such as swiping and pinching. The resistive model is equipped with DMC's light-touch resistive touch panel LST series, and touch controller which supports gesture operation, TSC-52 series. Touch monitors with a choice of design and safety features.

Stylish/Smart Touch Monitor is designed and tested to meet the quality and reliability requirements of industrial applications, and can be used for long periods of time. While the backlight life of consumer monitors is approximately 20,000 hours, the STM uses an LCD with a life of 50,000 hours. In addition, the panel display surface has a dustproof/waterproof structure equivalent to IP55, making it suitable for use in adverse environments with dust and water. The components used have been selected for their long-term availability and accessibility to ensure long-term stable production. If a component is discontinued, we will find an alternative component to continue the supply. DMC/Seedsware also provide thorough technical support, based on the experience and know-how cultivated over many years in the industrial market.

We also features a design that is flat and uncluttered, with no bezel step in both PCAP and resistive models. The compact and slim body features a panel thickness of only 18 mm(15.6”). The simple yet sophisticated design has black as the base color making it suitable for a wide range of equipment. This product is perfect for those who need to balance contemporary design with industrial reliability.

Stylish/Smart Touch Monitor also features a rotating control box on the back so that the position of the cables can be freely changed. As shown in the figure below, when the monitor is used in the horizontal direction and hung from the top, the cables come out from the horizontal direction, making cable layout difficult. The rear box can be rotated to allow cables to come out from the top so that cable layout will be neat.

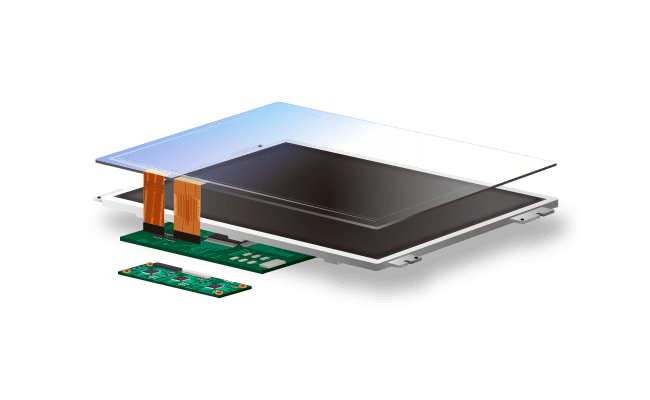

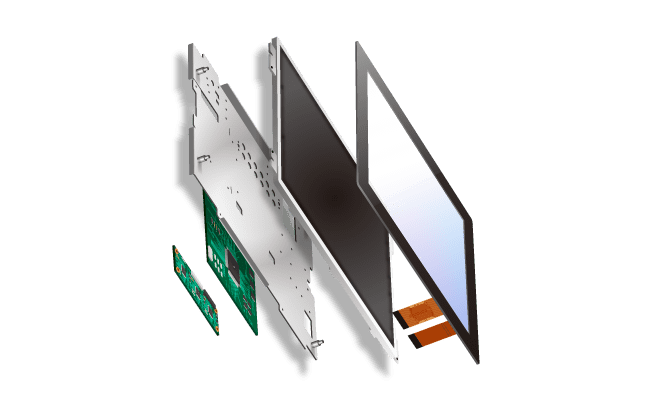

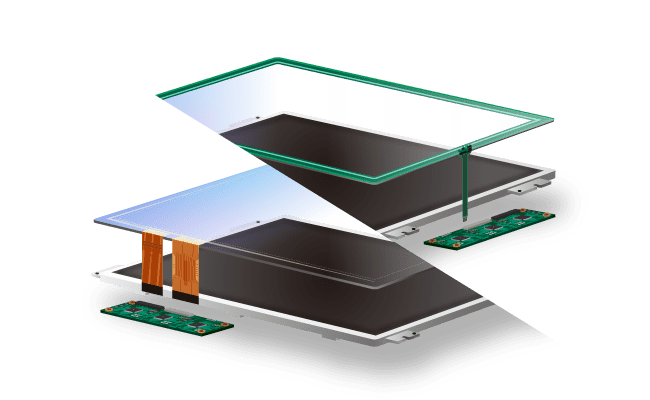

For equipment manufacturers who wish to incorporate the monitor into their own equipment, we offer only the LCD panel with touch panel and image processing board, without the case or chassis components.