Touchscreen surfaces and printing technology

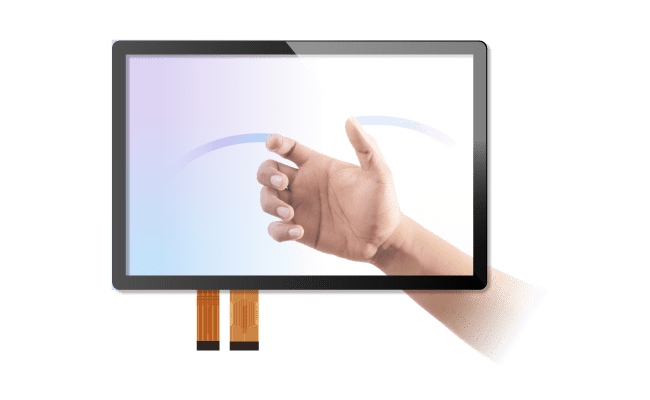

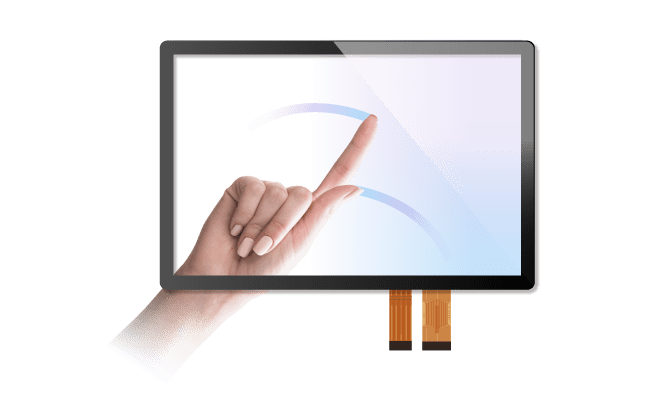

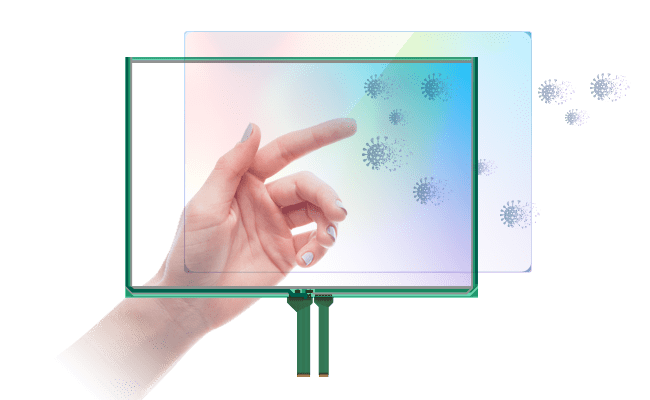

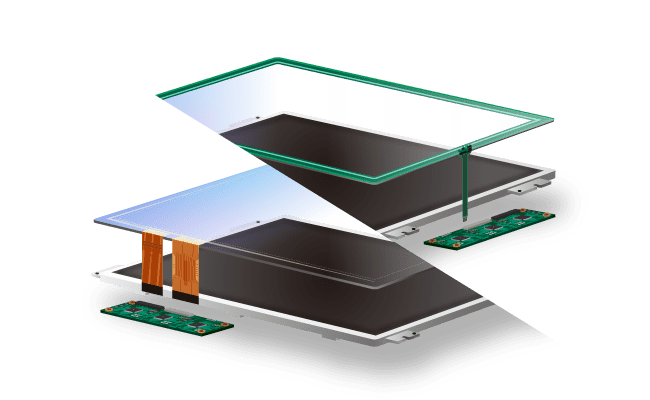

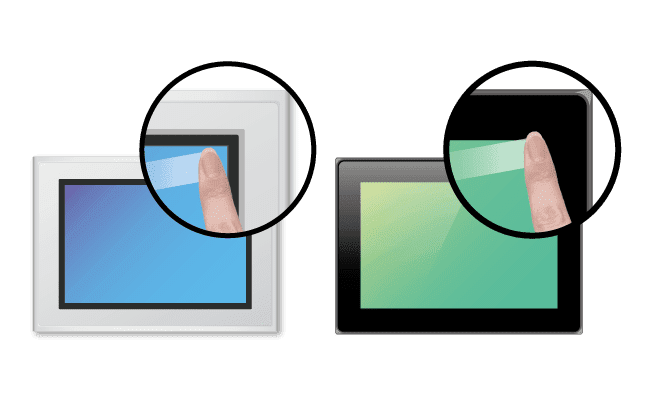

Branding makes an impression, creates recognition, builds credibility and grows equity. In the past, touch screen interfaces such as devices that we see in our daily lives were generally designed and branded at the bezel on the surface. However, with today’s prevalence of projective capacitive (PCAP) touch screens, the number of stylish flat designs that have an edge to edge cover glass has actually limited the options for product branding.

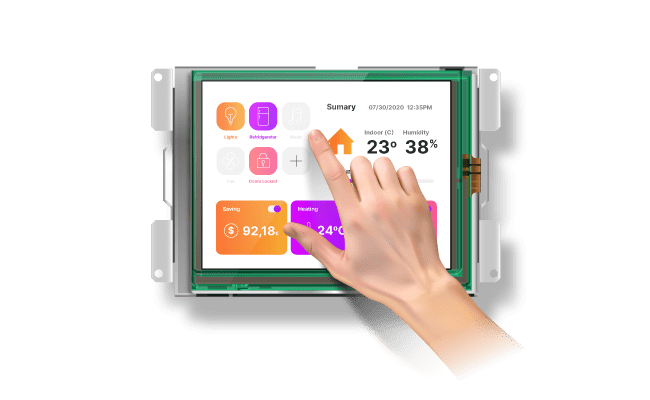

In today’s market, many prints displayed on the cover glass are all black. In the rare cases where a company or brand logo is printed or function keys are printed, screen printing is typically utilized. The choice of screen printing is typically constrained by cost (requires large lot size) or resolution (limited graphic options), DMC, with our introduction of new glass inkjet printing, can provide complex designs at lower cost and smaller lot size. As a result, customers now have options for a highly designed interface, even configurable or customizable in small lots, that can yield fast and easy differentiation from other companies.

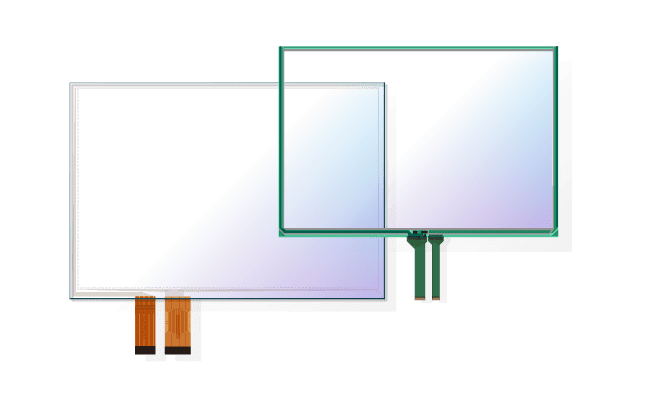

Use case for Screen printing

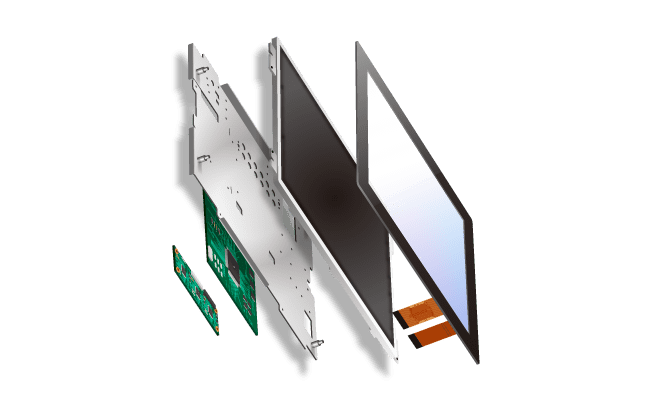

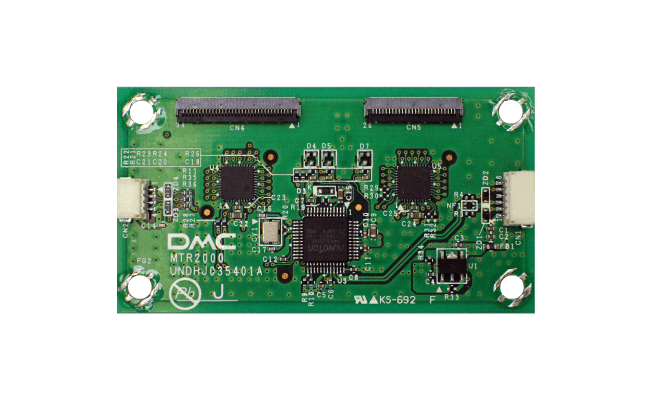

TOUCHSCREEN SOLUTION

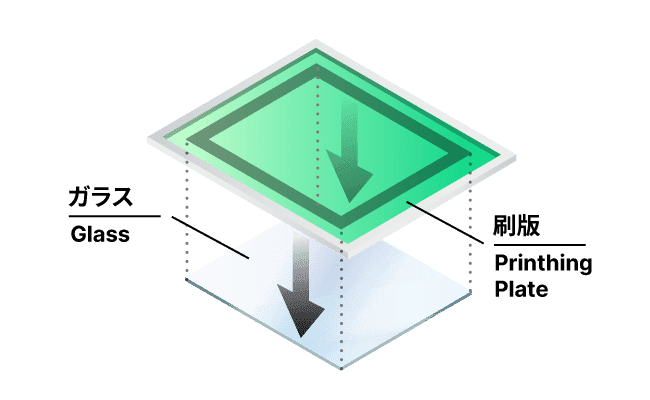

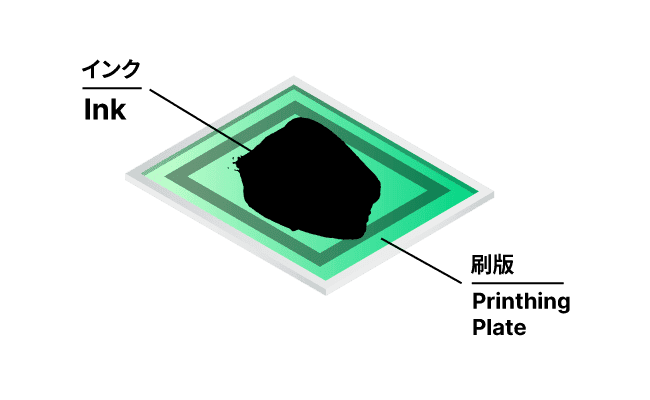

Screen printing is a printing method in which ink is transferred using a printing plate. Ink is transferred by pouring ink into a plate that has holes for passing ink in the area to be printed and pressing it against the glass. Because of the high production cost of the printing plate, it is not suitable for small lot variability. Once the printing plate is produced, it can be printed stably and many times. Also, screen printing is not suitable for high-definition printing; it requires a printing plate for each color, and the cost increases with multiple colors. Screen printing is best suited for simple designs with a small number of colors.

Benefits of inkjet printing

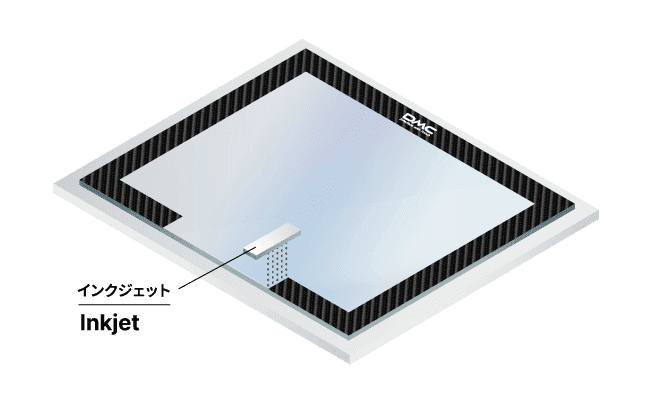

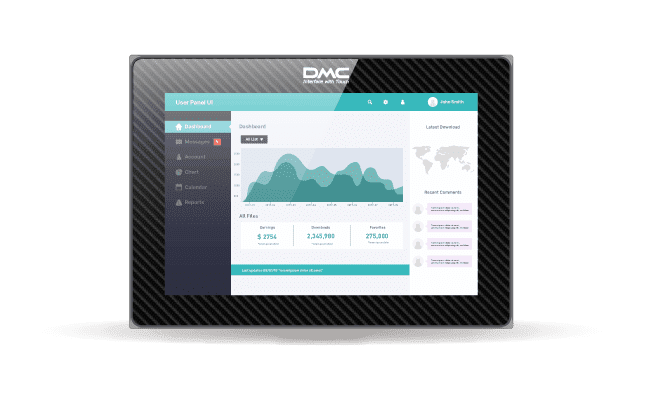

Inkjet printing is a printing method that sprays ink onto glass. Increasing the number of colors does not increase the cost. Inkjet printing supports high-definition imagery and complicated designs. By combining multiple color inks, more color choices are available including gradation colors. Customers can now create value-added designs such as original design expressions and high-class production. For example, the interface design of a touch monitor is generally based on a single color such as black or gray, but by making it carbon-like by inkjet printing, the texture is added to the appearance, and a profound and luxurious feeling can be produced.

Shorter lead time is another benefit: Inkjet printing does not require the production of printing plates, so the lead time for prototyping is shorter than screen printing, making it suitable for small lot production. In new design studies, we can prepare multiple proposals with short delivery time and reasonable cost.

Additionally the interface may have company or brand logos printed on it, but some logos incorporate gradations and subtle expressions. Inkjet printing can faithfully reproduce these elaborately designed logos without damaging your corporate or brand image.