Touchscreen Solutions for Harsh Operating Environments

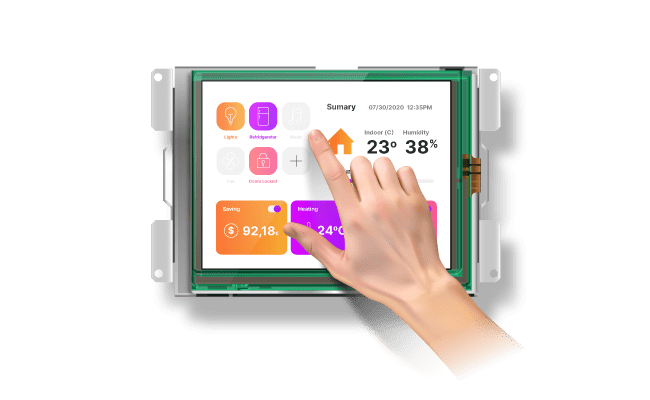

Touch screens that allow you to operate machines intuitively range from personal terminals such as smartphones to public terminals such as ticket vending machines, self-POS terminals, check-in terminals at airports and hotels, and business terminals such as operation terminals for medical equipment and factory equipment. It is used in every aspect of our lives and supports our lives.

Touch screens are often used in harsh environments. For example, touch screens mounted on snow guns and snow-packed vehicles used in ski resorts may be exposed to extremely cold temperatures of -20°C or less. In EV chargers and clearing machines in outdoor parking lots, the surface temperature becomes high when sunlight hits the touch screen for a long time, and the touch screen and LCD may be discolored or damaged in a short period of time due to the influence of ultraviolet rays.

In addition, the capacitive touch screen, which may malfunction if it gets wet with water, requires caution when used outdoors in the rain or in an environment with water around it, such as kitchen equipment and water jet processing machines. In addition, terminals installed in public places may be treated roughly or may be subject to unexpected shocks at factory worksites.

Most touch screens that are touched and operated by humans are mounted on the outermost surface of the device, so they are directly affected by these external influences. Therefore, it is necessary to select an appropriate touch screen and design the interface depending on the usage environment.

DMC's glass structure projected capacitive touch screen has characteristics and functions suitable for various usage environments, such as a wide operating temperature range, absorption characteristics of ultraviolet rays, and a function to prevent water malfunction.

Industrial grade glass structure PCAP Touchscreen

TOUCHSCREEN SOLUTION

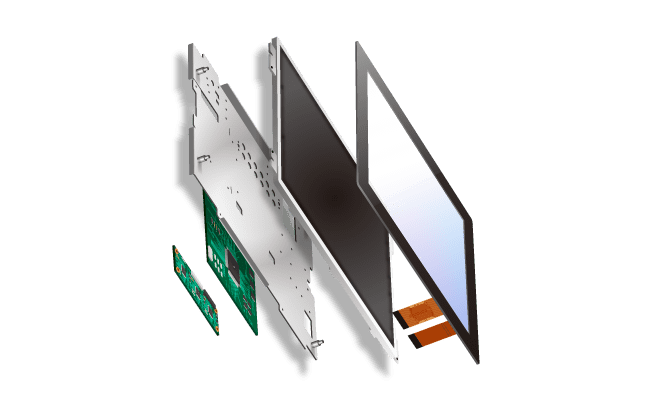

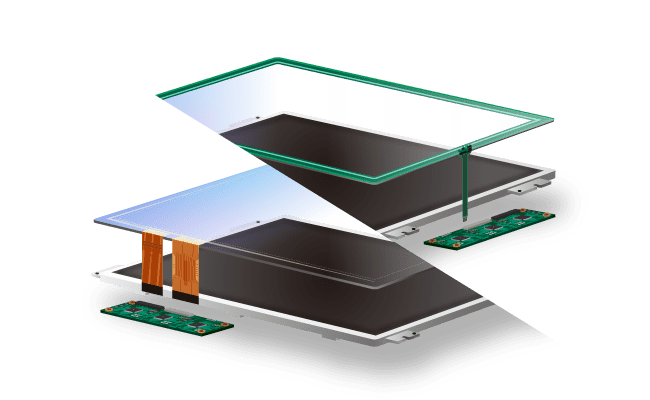

The "DUS-A series" has a structure in which two pieces of 1.1 mm thick glass are bonded together, and there is an electrode for sensing in the middle. Normally, tempered glass with a thickness of 1 to 3 mm is often used as a cover glass on the touch screen.

The DUS-A series has a highly robust structure by using laminated glass in this way. We are also developing the DFS series, which has a two-panel sensor structure and uses 0.55 mm thick thin glass for the upper / lower glass.

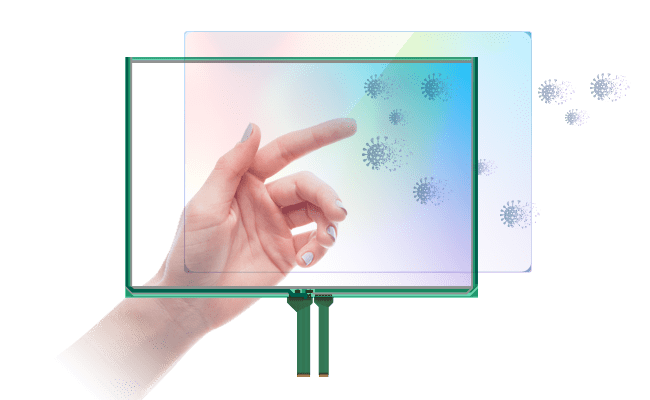

UV absorption characteristics

Glass structure: A material that absorbs ultraviolet rays is used for the adhesive layer between the glass of the projected capacitive touch screen and the glass, which has the effect of reducing the influence of ultraviolet rays on the LCD under the touch screen.

DMC's glass-structured projected capacitive touch screen with UV absorption characteristics is recommended for the operation terminal of outdoor facilities.

Water malfunction prevention function

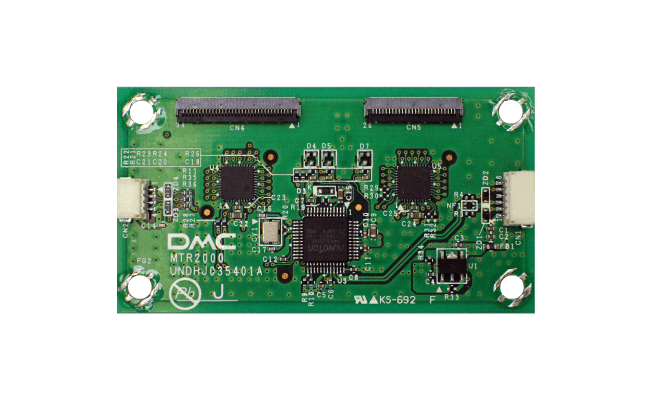

In the projected capacitance method, if the touch screen is wet, malfunctions such as inputting a place other than the touched position may occur. DMC's projected capacitive touch controller DUSx200 series detects water on the screen, issues an alarm, stops coordinate output until the water is wiped off, or limits it to one point, and adds malfunction prevention functions. It is a suitable solution for industrial equipment in rainy environments such as mobile terminals used at construction sites.

* For a touch interface which can get wet in an installed environment, in addition to a solution to prevent malfunction when its surface is wet, its housing needs to be designed in a water-proof way to prevent water from getting inside the interface which may cause troubles.

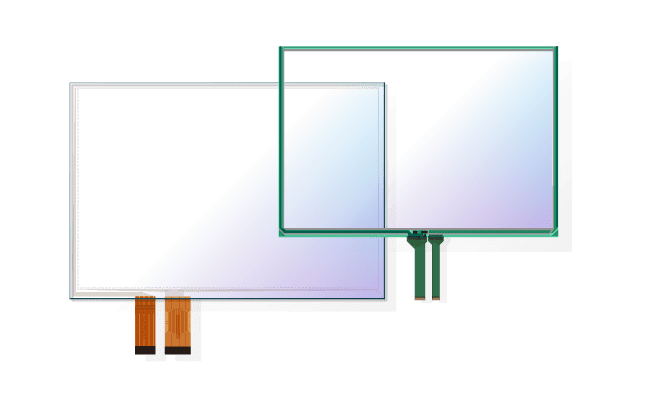

Impact resistant solution

Projected capacitive touch controllers can detect touch through glass or acrylic covers by increasing sensitivity. By using this, you can build a shock-resistant interface by installing an acrylic cover that is harder to break than glass in front of the touch screen with a gap. However, the thicker the cover, the higher the sensitivity is required, and since acrylic and air (gap) have a lower dielectric constant than glass, even higher sensitivity is required. On the other hand, if you increase the sensitivity too much, it will be more susceptible to ambient noise.

The DUSx200 touch controller has a track record of sensitivity adjustment with an air layer of 1 mm and an acrylic thickness of 3 mm as an impact resistant solution.